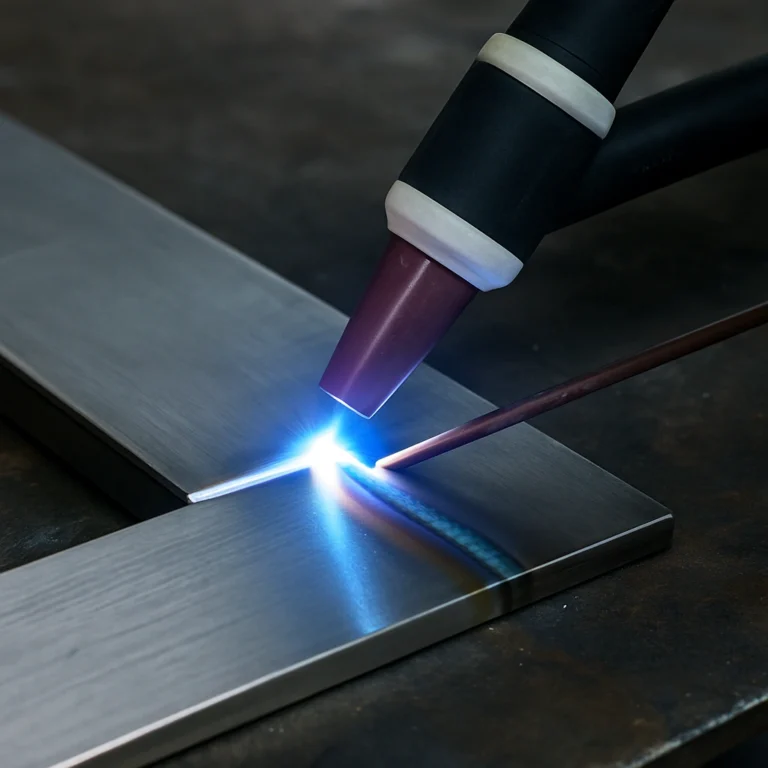

Best Welding Rods: Types, Uses, and How to Choose

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Last Updated: February 2026

Choosing the right welding rod depends on more than just material type or amperage range. Joint condition, welding process, base metal composition, and skill level all influence which electrode or filler rod produces reliable results.

Whether learning stick welding fundamentals or selecting filler metal for aluminum, stainless steel, or repair work, understanding how welding rods are classified and used is essential before narrowing down specific options. This guide organizes welding rod information by decision stage, material type, and application to help clarify what works best in different situations.

This page brings together welding rod guides covering comparisons, material-specific recommendations, and practical selection criteria. It’s designed to help readers understand which type of welding rod fits their needs before focusing on individual use cases.

🔍 Start Here: Understanding Welding Rod Basics

If welding rod numbers, classifications, or material compatibility feel unclear, these guides explain the fundamentals before comparing specific options.

These posts focus on how rods are classified and what those numbers indicate about strength, penetration, and usability.

🔍 Welding Rod Comparisons

When deciding between similar electrodes, direct comparisons help clarify performance differences and application limits.

- 308 vs 309 Welding Rod: Key Differences

- 6010 vs 7018 Welding Rod: What’s the Difference?

- 7014 vs 7018 Welding Rod Compared

Each comparison breaks down penetration behavior, surface tolerance, and typical use cases based on manufacturer data and AWS classifications.

🔍 Beginner and Learning-Focused Welding Rods

Some welding rods are better suited for learning fundamentals before moving into more demanding applications.

These guides focus on arc stability, ease of use, and learning progression rather than production welding.

🔍 Welding Rods for Dirty, Rusty, and Repair Work

Not all welding takes place on clean material. These guides focus on rods designed to tolerate surface contamination.

- Best Welding Rod for Rusty Metal

- What Is 6010 Welding Rod Used For?

- Best Amperage for 6010 Welding Rod

They explain when deeper penetration and surface tolerance matter more than appearance.

🔍 Aluminum Welding Filler Rods

Aluminum welding requires filler rods matched closely to alloy type and application.

- Most Common Aluminum Filler Rod Explained

- What Filler Rod for 6061 Aluminum Works Best?

- What Filler Rod for Cast Aluminum?

- Best TIG Rod for Cast Aluminum

These posts cover silicon vs magnesium fillers, crack resistance, and alloy compatibility.

🔍 Specialty Materials and Applications

Certain materials require filler rods with very specific properties.

These guides focus on preventing cracking, maintaining corrosion resistance, and matching base metal chemistry.

📌 Key Takeaways

- The “best” welding rod depends on material, surface condition, and application

- Rod numbers indicate strength, position capability, and flux behavior

- Beginners benefit from forgiving electrodes before progressing to higher-performance rods

- Aluminum, stainless, and cast iron require filler rods matched to alloy chemistry

- Understanding classification systems prevents poor weld performance and failures

✅ Conclusion

Choosing the right welding rod is less about brand and more about understanding how electrode classification, base metal type, and surface condition interact. By learning how different welding rods behave and where they’re best applied, it becomes much easier to select consumables that support consistent weld quality, skill development, and long-term reliability.