What Is MIG Welding? Process Basics Explained

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Last Updated: January 2026

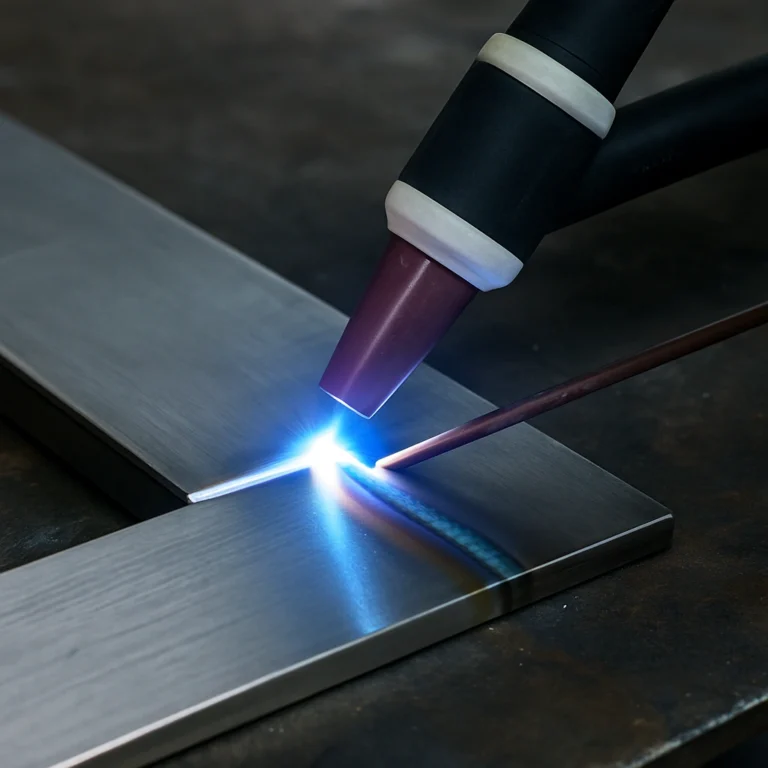

MIG welding is one of the most commonly used welding processes in home workshops, fabrication shops, and light industrial settings. Known for its continuous wire feed and relatively stable arc, MIG welding is often selected for projects that require clean welds, consistent results, and efficient workflow.

Based on manufacturer specifications, aggregated user feedback, and guidance from the American Welding Society (AWS), MIG welding is best understood as a gas-shielded arc welding process designed for speed, accessibility, and repeatability.

This guide explains what MIG welding is, how the process works, and where it is most commonly used.

👉 If you are deciding which welding process fits your needs overall, see best welding machines for a broader comparison.

📋 How We Evaluate Welding Processes

This research-based guide draws from:

- Manufacturer technical specifications

- Aggregated user feedback from verified purchasers

- Industry standards from organizations such as the American Welding Society (AWS)

- Application-specific requirements for common welding processes

We do not personally test equipment. All information reflects documented specifications, industry standards, and commonly reported use patterns.

🔍 What MIG Welding Means

MIG stands for Metal Inert Gas, although the process is more formally known as Gas Metal Arc Welding (GMAW) under AWS classification.

According to AWS definitions:

- A continuously fed wire electrode is supplied through a welding gun

- An electric arc forms between the wire and the base metal

- Shielding gas protects the molten weld pool from atmospheric contamination

This combination allows MIG welding to produce relatively clean welds with minimal slag compared to other welding processes.

🔍 How the MIG Welding Process Works

Manufacturer documentation and AWS guidance describe the MIG welding process as follows:

- The welding machine feeds wire automatically as the trigger is pulled

- Voltage and wire speed are set based on material thickness

- Shielding gas flows through the gun to protect the arc and weld pool

- The operator guides the gun while the machine maintains arc continuity

This semi-automatic operation contributes to MIG welding’s reputation for accessibility and efficiency.

🔍 Materials Commonly Welded With MIG

MIG welding is compatible with several common metals.

According to manufacturer specifications and AWS references, MIG welding is frequently used on:

- Mild steel

- Stainless steel

- Aluminum (with appropriate wire feed systems)

Material cleanliness and proper setup play a significant role in weld quality.

🔍 Gas MIG vs Flux-Core MIG

Some MIG-capable machines also support flux-core welding.

Based on manufacturer documentation:

- Gas-shielded MIG welding uses an external shielding gas and produces cleaner welds

- Flux-core welding uses tubular wire with flux and can be used without shielding gas

- Flux-core setups are often preferred for outdoor conditions where wind is a factor

While related, gas MIG and flux-core welding are considered distinct processes under AWS standards.

🔍 Where MIG Welding Is Commonly Used

AWS-aligned guidance and aggregated user feedback show MIG welding is widely used in:

- Home workshops and DIY projects

- Automotive repair and fabrication

- Light industrial manufacturing

- Maintenance and repair operations

Its combination of speed and consistency makes it suitable for repetitive welding tasks.

🔍 Limitations of MIG Welding

MIG welding is not ideal for every application.

According to AWS standards and user experience patterns, limitations include:

- Reduced effectiveness outdoors in windy conditions without flux-core wire

- Less tolerance for dirty or rusty materials compared to stick welding

- Limited suitability for highly positional structural welds

Understanding these limits helps determine when other welding processes may be more appropriate.

📌 Key Takeaways

- MIG welding is formally known as Gas Metal Arc Welding (GMAW)

- It uses a continuous wire electrode and shielding gas

- Commonly used for steel, stainless steel, and aluminum

- Favored for clean welds and efficient workflow

- Not ideal for all environments or materials

⚠️ Safety & Training Requirements

Welding involves significant electrical, fire, burn, and eye injury hazards. This guide provides general information only and does not substitute for:

- Proper welding training and certification

- Manufacturer safety instructions

- Electrical work performed by qualified electricians

- Appropriate personal protective equipment (PPE)

Consult certified welding instructors and follow all OSHA and AWS safety standards.

🟢 FAQs

Q: What does MIG stand for in welding?

According to AWS terminology, MIG stands for Metal Inert Gas, while the formal process name is Gas Metal Arc Welding (GMAW). Consult qualified professionals for personalized advice.

Q: Is MIG welding good for beginners?

AWS guidance and aggregated user feedback indicate MIG welding is commonly considered beginner-friendly due to stable arc characteristics and continuous wire feed. Consult qualified professionals for personalized advice.

Q: Is MIG welding the same as flux-core welding?

No. While some machines support both, gas MIG welding and flux-core welding are distinct processes under AWS standards. Consult qualified professionals for personalized advice.

✅ Conclusion

Based on manufacturer specifications, aggregated user feedback, and AWS-referenced standards, MIG welding is a widely used welding process valued for efficiency, accessibility, and consistent results. Understanding how the process works and where it performs best helps determine whether MIG welding is the right choice for a given application.