What MIG Welder Should I Buy? A Practical Decision Guide

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Last Updated: January 2026

Choosing a MIG welder is often the next step after deciding that MIG welding is the right process—but that doesn’t automatically mean buying the most powerful or most popular machine. The right MIG welder depends on materials, power access, project scope, and how quickly skills are expected to develop.

Based on manufacturer specifications, aggregated user feedback, and AWS (American Welding Society) guidance, most MIG welder buying mistakes happen when machines are chosen for maximum output instead of realistic use.

This guide explains how to decide what type of MIG welder makes sense before looking at specific models.

👉 If you’re still deciding between MIG, stick, or TIG welding overall, see best welding machines for a broader comparison.

📋 How We Evaluate MIG Welder Selection

This research-based guide evaluates MIG welder selection using:

- Manufacturer technical specifications

- Aggregated user feedback from verified purchasers

- Industry standards from organizations such as the American Welding Society (AWS)

- Application-specific requirements for common MIG welding tasks

We do not personally test equipment. Guidance reflects documented specifications, usage patterns reported by users, and alignment with industry standards. Readers should verify compatibility with their specific projects and consult certified professionals when appropriate.

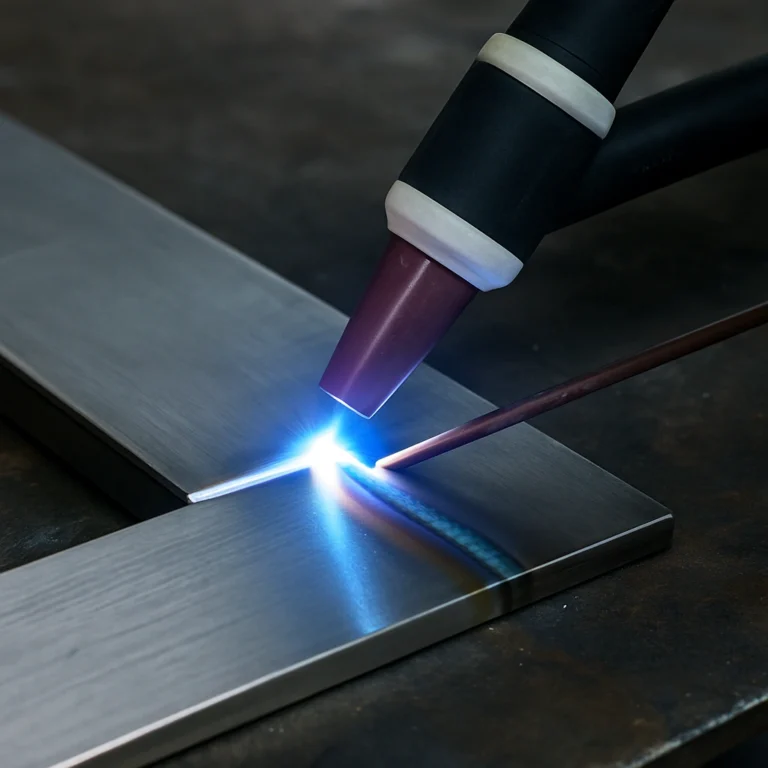

🔍 Start With the Material You Plan to Weld

The most important factor in choosing a MIG welder is the material itself.

According to AWS guidelines and manufacturer data:

- Thin-gauge steel and sheet metal require stable low-amperage control

- Thicker mild steel demands higher sustained output and appropriate duty cycle

- Aluminum welding requires spool gun support or specialized MIG configurations

- Stainless steel benefits from consistent wire feed and heat control

Choosing a MIG welder that exceeds material needs often adds cost and complexity without improving results.

🔍 120V vs 230V MIG Welders: Power Matters

Power availability significantly affects usable output.

Manufacturer specifications and user feedback indicate:

- 120V MIG welders prioritize portability and convenience and are commonly used for light fabrication and home projects

- 230V MIG welders provide higher amperage and longer duty cycles for thicker materials

- Dual-voltage MIG welders offer flexibility but may increase cost and setup requirements

Industry standards recommend consulting a licensed electrician before installing or operating 230V welding equipment.

🔍 Amperage and Duty Cycle: What to Focus On

Maximum amperage ratings can be misleading without context.

AWS standards emphasize:

- Duty cycle determines how long welding can continue before overheating

- Stable output at working amperage is more important than peak ratings

- Oversized machines do not improve results on thin materials

Matching realistic output to project needs leads to better weld quality and fewer interruptions.

🔍 Gas MIG vs Flux-Core MIG

Many MIG welders support both gas-shielded MIG and flux-core welding.

According to manufacturer documentation and user feedback:

- Gas MIG produces cleaner welds with less spatter but requires shielding gas

- Flux-core MIG works better outdoors and tolerates surface contamination

- Dual-capability machines offer flexibility but may add setup steps

Understanding how and where welding will take place helps determine which capability matters most.

🔍 Learning Curve and Control Features

Ease of learning plays a major role for beginners.

User experience patterns show:

- Simple voltage and wire-speed controls reduce setup frustration

- Excessive advanced features can slow early skill development

- Clear labeling and stable arc characteristics support consistent learning

A MIG welder that prioritizes control and predictability is often more effective than one with maximum feature density.

🔍 Portability, Size, and Workspace Fit

Practical considerations are frequently underestimated.

User feedback commonly highlights:

- Compact inverter MIG welders are easier to store and transport

- Heavier machines may offer higher duty cycles but limit mobility

- Workspace size and ventilation affect machine choice

A welder that fits the workspace is more likely to be used regularly.

📌 Key Takeaways

- Start with material type and thickness before comparing machines

- Power availability limits usable output more than advertised amperage

- Duty cycle matters more than peak ratings

- Flux-core capability adds flexibility for outdoor work

- Simpler controls often support faster learning

⚠️ Safety & Training Requirements

Welding involves significant electrical, fire, burn, and eye injury hazards. This guide provides general equipment information only and does not substitute for:

- Proper welding training and certification

- Manufacturer safety instructions

- Electrical work performed by qualified electricians

- Appropriate personal protective equipment (PPE)

Consult certified welding instructors and follow all OSHA and AWS safety standards.

🟢 FAQs

Q: What MIG welder should a beginner buy?

According to AWS guidance and aggregated user feedback, beginners often benefit from MIG welders that prioritize stable arcs, simple controls, and appropriate power for thin to medium steel. Consult qualified professionals for personalized advice.

Q: Is a more powerful MIG welder always better?

No. AWS standards emphasize matching output and duty cycle to material thickness rather than choosing maximum amperage. Consult qualified professionals for personalized advice.

Q: Do I need gas capability on a MIG welder?

Gas capability is useful for cleaner welds indoors, while flux-core welding is more tolerant of outdoor conditions. Manufacturer specifications can help determine supported configurations. Consult qualified professionals for personalized advice.

✅ Conclusion

Based on manufacturer specifications, aggregated user feedback, and AWS-referenced standards, deciding what MIG welder to buy comes down to materials, power access, learning goals, and workspace constraints. A MIG welder matched to realistic projects and operating conditions will be more effective than one chosen solely on advertised specifications.