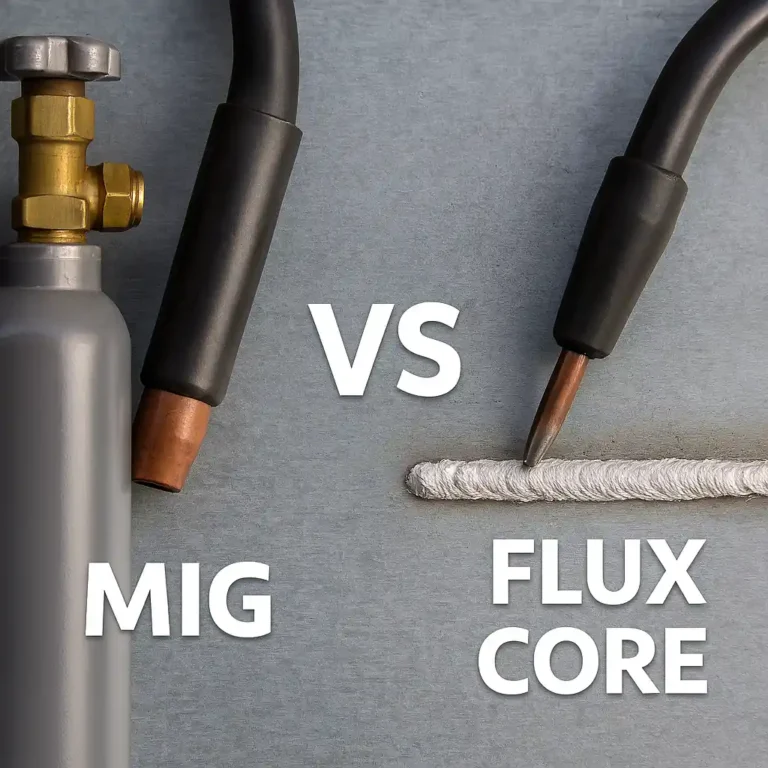

MIG vs Flux Core Welding: Choosing the Right Process for Your Needs

Welding is a foundational skill in metalwork, and for beginners and professionals alike, understanding the difference between MIG and flux core welding is essential. Each method has its own advantages, ideal use cases, and limitations. Choosing the right one can influence your project outcomes, welding efficiency, and long-term satisfaction with your gear. Understanding the Basics…