What Is TIG Welding? A Clear, Beginner-Friendly Guide

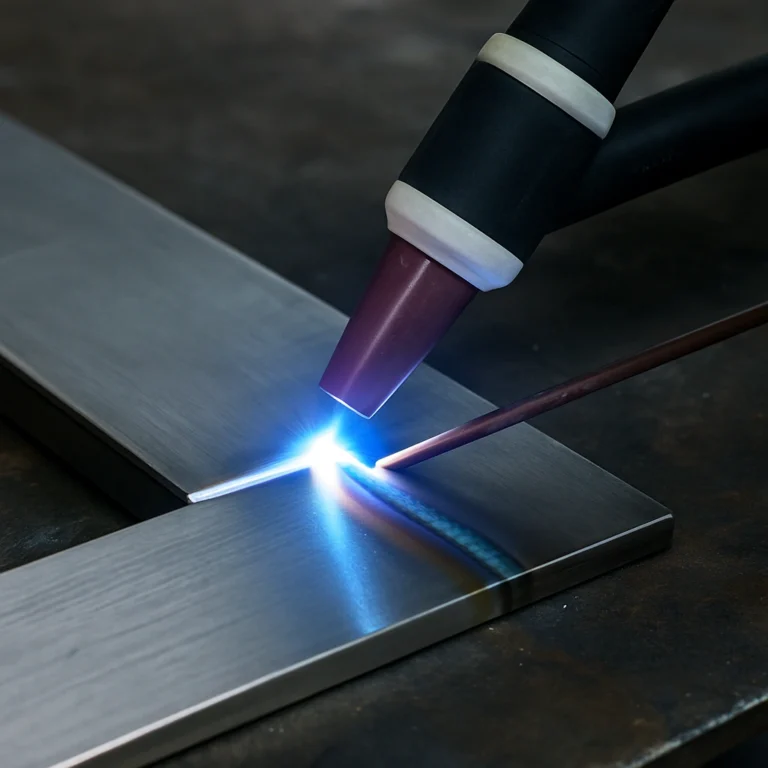

Last Updated: November 2025 TIG welding is all about precision. It gives you steady heat control and a clean, calm puddle, which is why welders turn to it when appearance and accuracy matter. When you spot those smooth “stacked dime” beads on stainless, that’s almost always a TIG pass done right. TIG does take more…