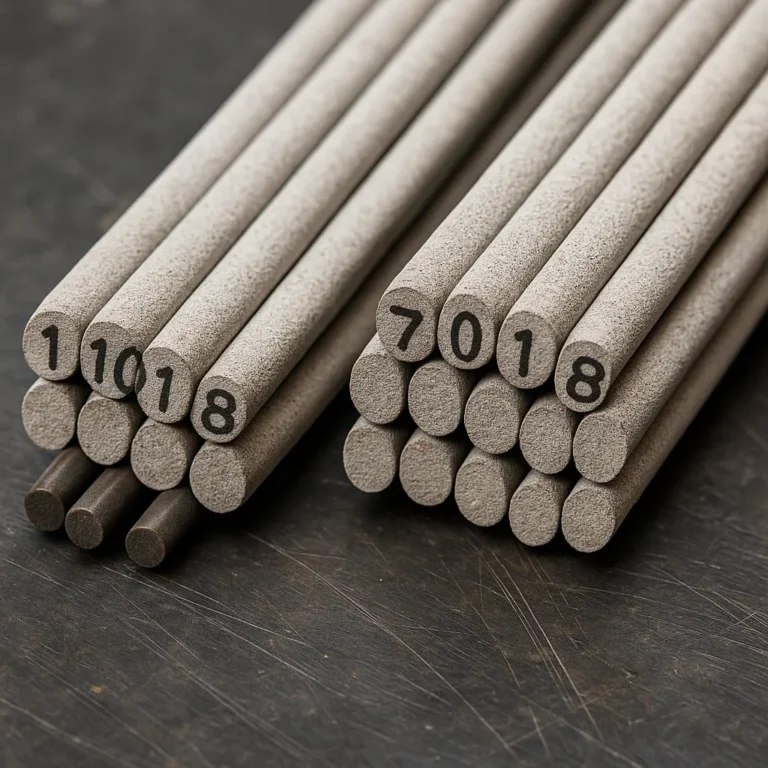

Best Welding Rod for Rusty Metal – Built for Tough Surfaces

Last Updated: September 13, 2025 Rusty steel will test your patience. The arc skips, the puddle won’t tie in, and cracks show up quick if you don’t pick the right rod. Choosing the best welding rod for rusty metal saves time, reduces grinding, and gives welds that hold. 👉 If you’re brushing up on rod…