How to Stick Weld for Beginners – Rugged Setup Tips That Make Learning Easier

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Last Updated: August 5, 2025

Stick welding isn’t the cleanest or quietest process—but it works where others don’t. It doesn’t care if your metal’s dirty, if there’s wind, or if your gear’s a little beat up. That’s why so many beginners start here—it’s cheap, tough, and gets the job done when nothing else will.

If you’re still pulling your setup together, our beginner welder setup guide covers the core gear to have on hand before you strike your first arc.

Choosing the Right Welder for Stick

You don’t need a fancy welder to run stick. Inverter machines are light, portable, and plug into a regular outlet. They’re perfect for learning at home or doing repairs in the yard.

Stick is great when you’re working in rough conditions. You don’t need gas, you don’t need clean steel, and you don’t have to worry about wind messing up your weld. That makes it ideal for outdoor work, fences, trailers, and shop repairs.

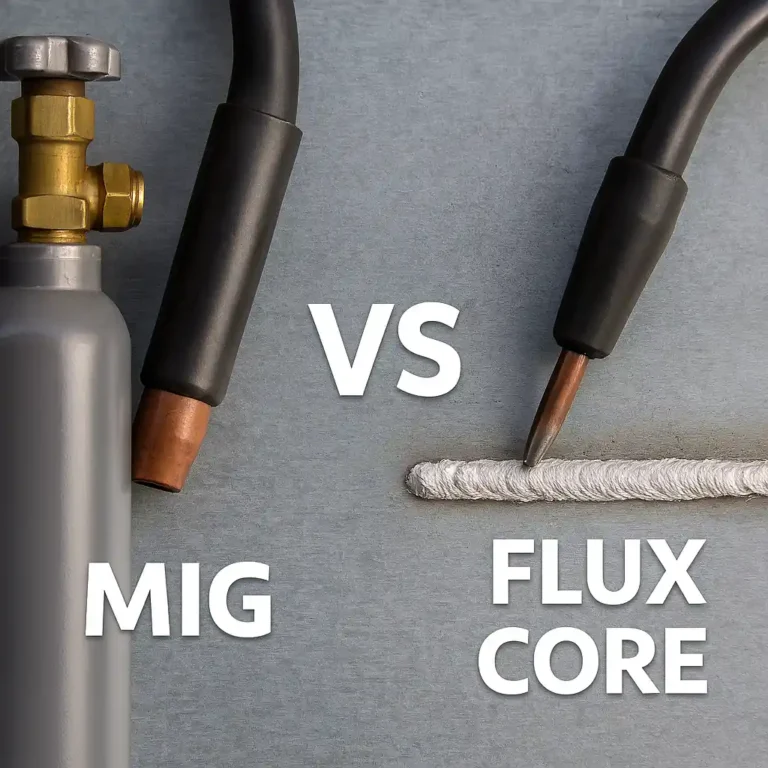

Here’s how stick stacks up against the others:

| Process | Best For | Pros | Cons |

|---|---|---|---|

| Stick | Dirty or outdoor work | Cheap, tough, no gas needed | Messier welds, more spatter |

| MIG | Indoor fab work | Easy to run, cleaner results | Needs gas, doesn’t like wind |

| TIG | Precision jobs | Super clean and smooth | Slow, takes more skill and prep |

For most beginners, a 90–130 amp welder is plenty to run 1/8″ rods. Dual-voltage machines come in handy if you’re switching between home and jobsite outlets.

Safety Gear You Can’t Skip

Stick welding puts off more heat, smoke, and slag than most other processes—so your safety gear needs to be up to the task.

- Auto-darkening helmets with a quick lens response help you keep track of the puddle and reduce eye strain. Stick typically runs fine at shade 10–12. A slow-reacting lens makes tack work way harder than it needs to be.

- Thick gloves are a must. You’re dealing with hot rods and heavy slag, so padding helps without giving up too much feel. A heavy cotton or leather-sleeve jacket adds solid protection without cooking you.

- Welders have learned the hard way—boots matter. Go for leather uppers and skip anything with mesh. And if you’re welding inside, even a cracked garage door or small fan makes a big difference for clearing smoke.

Setting Up Your Welding Space

Stick is simple—but your workspace still needs to be safe and smart.

Make sure you’re working near ventilation if you’re indoors. Even though you don’t use gas, stick puts out a lot of smoke—especially on painted or rusty metal. A garage with a fan, or an open shed, works fine.

A metal plate on saw horses or a grounded steel bench gives you a solid welding surface. Just keep it clear of wood or flammable clutter. Light matters too. Stick puddles aren’t always easy to see, especially if you’re burning through rust.

Tidy leads, a solid ground clamp, and some elbow room all help you move smoothly once you’re mid-bead.

Tool Storage & Power Management

Even with stick welding’s low-tech setup, a little organization goes a long way.

Having a cart or shelf for your welder, leads, gloves, and rods saves time and keeps your space cleaner. Wrap up your cables when you’re done—they’ll last longer and be easier to set up next time.

Stick machines pull decent amps. If you’re running 110V, don’t plug into an outlet that’s also running a grinder or shop vac. For 240V, a dedicated circuit is your best bet. You’ll notice fewer arc interruptions and better weld consistency.

💡 Tip: “If you’re using 7018 rods, store them sealed up. Damp rods lead to frustrating arc starts and messy welds.”

What’s Worth Spending More On?

Stick is budget-friendly—but a couple of smart upgrades can make the whole process smoother.

A decent helmet is a top priority. You’ll feel the difference right away in arc visibility, comfort, and eye fatigue. Don’t go bottom shelf here.

Rods matter too. Cheaper ones tend to spatter more and run less consistently. Plenty of welders trust Lincoln and Hobart for smoother starts and cleaner arcs.

Leads are another place where quality counts. Stiff cables make it harder to move around, especially when it’s cold. That’s a big deal on longer jobs. You can save on clamps, brushes, and even chipping hammers—just don’t skimp on what keeps your arc steady.

FAQ – Stick Welding for Beginners

What’s the easiest rod to start with?

6013 is a good beginner pick—easy to strike and forgiving. 7018 gives cleaner welds but takes a bit more practice.

Do I need to clean the metal before welding?

Stick can handle some rust and paint, but you’ll still get better results if you knock off loose debris first.

Can I weld outside on a breezy day?

Yes—that’s where stick shines. Wind won’t mess with your arc like it does with MIG or TIG.

Will a standard outlet work?

Most inverter stick welders run fine on 120V, but make sure you’re not sharing the circuit with other tools.

Conclusion

If you’re just getting into welding or need a tough, low-maintenance process for field work, stick welding is a smart place to start. It’s forgiving, affordable, and doesn’t demand perfect conditions. Set up your space right, use the right gear, and you’ll be stacking solid beads in no time.