Lincoln AC 225 Welder Review: Classic Power for Stick Welding Jobs

The Lincoln Electric AC 225 is a staple in the world of stick welding, known for its bulletproof reliability and ease of use. Designed for home users, hobbyists, and farm work, this machine has earned its place in countless workshops thanks to its rugged construction and consistent arc performance. But how does it hold up in today’s market filled with flashy inverter models? Let’s take a closer look.

Overview of the Lincoln Electric AC225

The Lincoln Electric K1170 AC225 is a transformer-based stick welder that delivers up to 225 amps of welding power. Operating on standard 230V input, it supports a wide range of electrodes, making it suitable for welding mild steel, stainless steel, and cast iron. While it doesn’t offer DC output or multi-process versatility, it compensates with unmatched durability and simplicity.

Key Features

Proven Transformer Technology

One of the AC 225’s defining features is its heavy-duty transformer core. Unlike inverter welders, it doesn’t rely on sensitive electronics, making it less prone to failure and better suited for rough environments. The arc is stable, especially above 100 amps, and perfect for penetrating thicker materials.

Amp Range and Electrode Compatibility

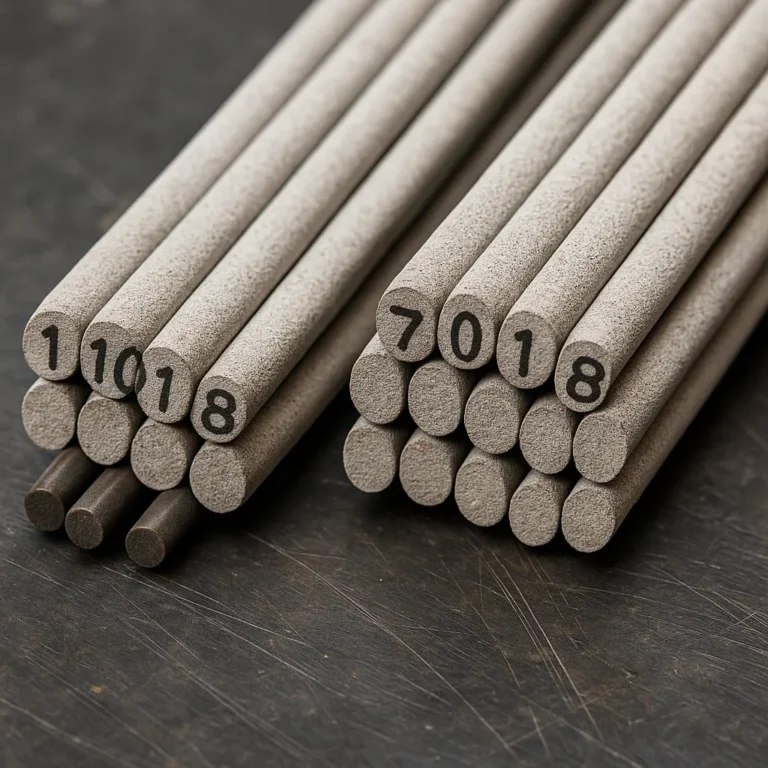

With an output range from 40 to 225 amps, this machine can easily handle rods from 1/16” to 5/32”. It’s well-suited for 6011, 6013, and 7018 electrodes, giving users the flexibility to tackle both light repairs and heavier fabrication.

Rugged Build and Longevity

The AC225 features a robust metal case, analog dial selector, and ventilation designed for high-duty cycles. It’s not portable by modern standards—it weighs over 100 pounds—but what it lacks in mobility, it more than makes up for in durability.

Performance in the Field

Welders who favor the AC 225 often praise its consistent arc, especially for vertical and overhead positions. The arc starts reliably, and spatter is manageable once the amperage is dialed in correctly. The unit is ideal for welding thicker materials where AC-only current is sufficient. However, it’s not the best for thin sheet metal or precise TIG applications.

Pros and Cons

Pros

- Rock-solid reliability

- Great for beginners and farm/ranch work

- Excellent arc performance on AC

- Compatible with common stick electrodes

- Long lifespan with minimal maintenance

Cons

- Heavy and not easily portable

- Lacks DC or TIG capabilities

- Not suitable for aluminum or thin metal

Conclusion

The Lincoln Electric AC 225 continues to prove its worth as a dependable, straightforward stick welder. For users who don’t need digital interfaces or multi-process options, this classic machine delivers strong, consistent performance with minimal fuss. Whether you’re a weekend welder or managing equipment on a farm, the AC 225 is a tool you can trust for years to come.