Best Stick Welder for Farm Use: Tough Machines Built for Rugged Jobs

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

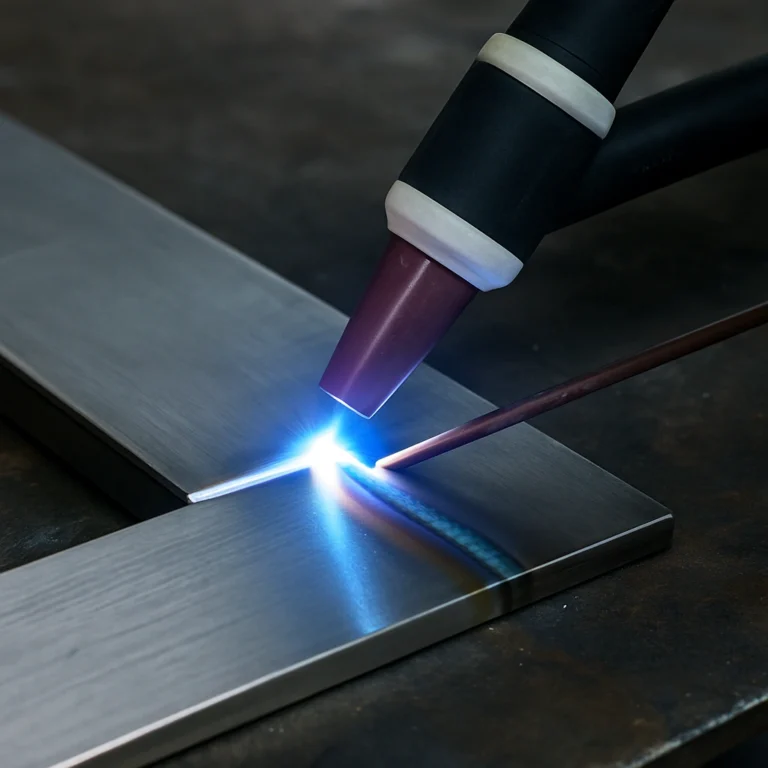

Every farmer knows that a reliable welder is one of the most essential tools in the shop. From repairing broken gates and tractors to building frames and machinery, having the best stick welder for farm use can mean the difference between a quick fix and days of downtime. Stick welding remains the top choice for outdoor farm repairs due to its versatility, portability, and ability to perform well in dirty or windy conditions. Let’s take a look at three high-performance welders that combine toughness with value to meet the unique needs of farm work.

TOOLIOM 135A 110V Stick Welder MMA ARC Welder Machine Review

Compact but powerful, the TOOLIOM 135A delivers strong arc performance and portability, making it an ideal choice for farm users working across large areas or off-grid locations. Its DC inverter design improves energy efficiency and offers a more stable arc, which is perfect for welding a variety of farm-grade materials like mild steel and iron.

This model runs on 110V, so it’s plug-and-play ready for most farm outlets. The welder features a clear digital display and intuitive controls, enabling quick setup even for those with minimal welding experience. It’s a great entry-level welder or a backup unit for heavier-duty shop models, with a price point that makes it a smart investment for routine maintenance jobs.

HONE Stick Welder, 110V/220V Actual 140Amp ARC Welder Machine Review

If your welding needs vary from light repairs to more demanding work, the HONE 140Amp stick welder offers impressive flexibility with its dual-voltage capabilities. This inverter welder provides consistent arc performance on both 110V and 220V, handling 1/16″ to 1/8″ welding rods without issue.

Farmers will appreciate its hot start and anti-stick functions, which prevent frustrating electrode snags and ensure smooth starts on rusty, painted, or dirty metal—common challenges on outdoor equipment. The digital LCD and lightweight frame make it practical for mobile jobs, and its IGBT technology ensures reliable output even when welding in unpredictable conditions.

YESWELDER Stick Welder 205Amp Large LED Display Review

For farmers who need a bit more power without giving up portability, the YESWELDER 205Amp stick welder delivers. It features dual voltage (110V/220V) input and supports a wide range of electrodes, offering both power and adaptability. Its high-duty cycle means you can take on extended repair sessions without worrying about overheating or downtime.

The welder’s hot start, arc force, and anti-stick technologies improve ignition and reduce electrode sticking, making it ideal for working on tough farm steel in various outdoor conditions. The large LED display offers excellent visibility, even under bright sunlight or in dimly lit barns, making it an ideal tool for daily on-site repairs.

Conclusion

Choosing the best stick welder for farm use means balancing rugged reliability with the flexibility to handle diverse repair needs. Whether you’re welding rusty tractor parts, reinforcing metal gates, or fabricating new components, the TOOLIOM 135A, HONE 140A, and YESWELDER 205A all deliver excellent performance at great value. Investing in any of these will ensure that your welding equipment is just as tough as the work you face every day on the farm.