Welding Tools and Equipment List: What You Actually Need

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Last Updated: January 2026

Welding requires more than just a welding machine. Safety gear, preparation tools, and basic accessories all play a role in producing consistent welds and reducing risk.

Based on manufacturer specifications, aggregated user feedback, and guidance aligned with American Welding Society (AWS) standards, this guide outlines the essential welding tools and equipment commonly required for safe and effective welding across beginner and intermediate applications.

This article focuses on what tools are used, why they matter, and when they are typically required, not on specific product recommendations.

👉 For a full breakdown of welding machine types and use cases, see best welding machines.

📋 How We Evaluate Welding Tools and Equipment

This research-based guide is built using:

- Manufacturer technical documentation

- AWS safety and process standards

- Aggregated user feedback from training and workshop environments

- Common application requirements across welding processes

We do not personally test tools or equipment. Information reflects industry standards, documented specifications, and widely accepted welding practices.

🔍 Core Welding Equipment

These items form the foundation of any welding setup.

Welding Machine

The welding machine supplies power and controls arc characteristics. The type required depends on the welding process (MIG, TIG, Stick) and application.

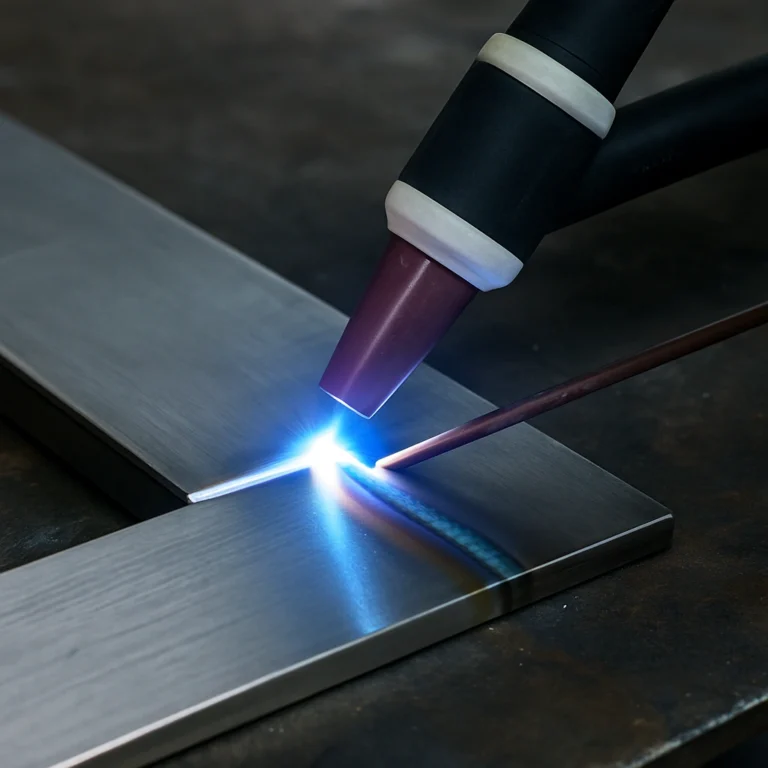

Welding Gun, Torch, or Electrode Holder

Used to deliver current to the weld:

- MIG guns feed wire and shielding gas

- TIG torches hold tungsten electrodes

- Stick electrode holders clamp welding rods

These components are process-specific and essential for arc control.

Work Clamp (Ground Clamp)

The work clamp completes the electrical circuit. Poor grounding can cause unstable arcs and inconsistent weld quality.

🔍 Personal Protective Equipment (PPE)

AWS safety standards emphasize PPE as mandatory, not optional.

Welding Helmet

Protects eyes and face from arc radiation and spatter. Auto-darkening helmets are commonly used for visibility and convenience.

Welding Gloves

Designed to protect hands from heat, sparks, and sharp edges while maintaining dexterity.

Protective Clothing

Commonly includes:

- Flame-resistant jackets or sleeves

- Long pants made from non-synthetic materials

- Leather aprons or bibs

These reduce burn risk from spatter and radiant heat.

🔍 Joint Preparation and Cleanup Tools

Surface preparation directly affects weld quality.

Angle Grinder

Used for:

- Removing rust, paint, or coatings

- Beveling edges

- Cleaning welds

Wire Brushes

Help clean metal before and after welding. Material type should match the base metal to avoid contamination.

Clamps and Magnets

Hold workpieces in alignment during tack welding and assembly.

🔍 Measuring and Layout Tools

Accurate fit-up improves weld consistency.

Common tools include:

- Tape measures

- Squares

- Markers or soapstone

- Levels

These tools help ensure proper joint geometry before welding begins.

🔍 Consumables Used in Welding

Consumables vary by process.

According to manufacturer documentation:

- MIG welding uses solid or flux-cored wire

- Stick welding uses coated electrodes

- TIG welding uses filler rods and tungsten electrodes

Shielding gas cylinders and regulators are also required for gas-shielded processes.

🔍 Power and Electrical Accessories

Safe power delivery is critical.

Typical accessories include:

- Extension cords rated for welding current

- Power adapters or plugs

- Surge protection where applicable

Industry standards recommend electrical work be handled by qualified electricians.

🔍 Optional but Common Workshop Tools

While not mandatory, many workshops also use:

- Welding carts

- Chipping hammers

- Welding tables

- Fume extraction or ventilation systems

These improve workflow, cleanliness, and safety.

📌 Key Takeaways

- Welding requires a combination of machines, tools, and safety equipment

- PPE is mandatory under AWS safety standards

- Proper preparation tools improve weld quality

- Consumables vary by welding process

- Supporting tools enhance safety and efficiency

⚠️ Safety & Training Requirements

Welding involves significant electrical, fire, burn, and eye injury hazards. This guide provides general information only and does not substitute for:

- Proper welding training and certification

- Manufacturer safety instructions

- Electrical work performed by qualified electricians

- Appropriate personal protective equipment (PPE)

Consult certified welding instructors and follow all OSHA and AWS safety standards.

🟢 FAQs

Q: Do beginners need all welding tools right away?

According to training guidance and user feedback, beginners can start with essential safety gear and basic preparation tools, expanding as projects become more complex. Consult qualified professionals for personalized advice.

Q: Are welding accessories interchangeable between processes?

Some tools, such as grinders and clamps, are shared, but torches, electrodes, and consumables are process-specific. Consult qualified professionals for personalized advice.

Q: Is PPE legally required for welding?

AWS and OSHA safety standards require appropriate protective equipment for welding operations. Consult qualified professionals for personalized advice.

✅ Conclusion

Based on AWS-referenced standards and manufacturer documentation, welding tools and equipment extend far beyond the welding machine itself. Understanding which items are essential—and why they matter—helps support safer setups, better weld quality, and more efficient workflow across a wide range of welding applications.