What Gas Is Used for MIG Welding? Shielding Gases Explained

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

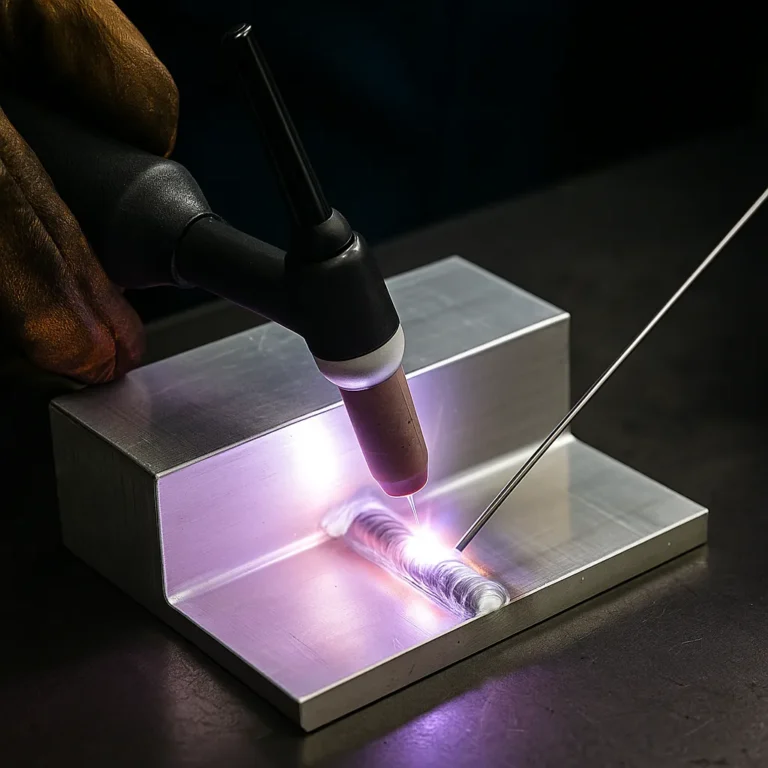

Gas Metal Arc Welding (GMAW), better known as MIG welding, relies on shielding gas to protect the weld from contamination. Without it, atmospheric gases like oxygen and nitrogen would cause porosity, weak joints, and excessive spatter. However, not all shielding gases are created equal—different gases influence arc characteristics, weld appearance, penetration, and even the cost of operation. So what gas is used for MIG welding? The answer depends on your project, material, and desired outcome.

Why MIG Welding Requires Shielding Gas

MIG welding uses a continuous wire feed to join metals, creating an electric arc between the wire and the workpiece. This process generates intense heat, which can oxidize the molten weld pool if exposed to air. Shielding gas flows from the MIG gun to protect the weld zone from these harmful elements.

Unlike flux-core welding, which produces its own shielding through internal flux, MIG welding depends entirely on an external gas source. Choosing the right gas is crucial for achieving strong, clean, and consistent welds.

Common Shielding Gases for MIG Welding

Several gases and gas mixtures are used in MIG welding, each suited to different applications. Here’s a breakdown of the most common options:

Argon

Pure argon is a stable, inert gas commonly used for MIG welding non-ferrous metals such as aluminum, magnesium, and titanium. It produces a smooth, stable arc and minimal spatter but provides shallow penetration when used alone on steel.

Carbon Dioxide (CO₂)

100% CO₂ is the most cost-effective shielding gas for MIG welding and is widely used in industrial applications. It offers deep weld penetration and strong fusion, making it ideal for structural steel. However, it tends to create more spatter and a less stable arc compared to argon-based blends.

Argon-CO₂ Mixtures

The most popular MIG welding steel blend is 75% argon and 25% CO₂, often referred to as C25. This mix balances arc stability, low spatter, good penetration, and improved weld appearance. It’s a go-to choice for automotive work, fabrication, and general repair welding.

Other mixtures, like 90% argon/10% CO₂ or 80% argon/20% CO₂, can fine-tune performance depending on the job.

Argon-Helium Mixtures

Argon-helium blends are typically used for non-ferrous metals or when higher heat input is needed. Helium enhances penetration and speeds up the welding process, but it’s more expensive and requires higher flow rates.

Specialty Mixtures

Gases like oxygen or hydrogen are sometimes added in small percentages to argon for specific materials or conditions. These are mostly used in advanced or automated industrial processes and are not commonly required for general MIG welding.

Choosing the Right Gas for the Job

- Mild Steel: For the best results, use a C25 argon/CO₂ mix. 100% CO₂ is an option for cost savings, but it produces more spatter.

- Stainless Steel: For cleaner welds, use a tri-mix (argon, CO₂, and helium) or a specialized, argon-rich blend.

- Aluminum: Use 100% argon or argon-helium if deeper penetration is needed.

- Thicker Metals: Consider adding helium to your gas mix to improve heat transfer and penetration.

Conclusion

Selecting the right shielding gas is essential for high-quality MIG welds. Argon and CO₂ in various combinations cover most applications, offering flexibility for different materials and welding conditions. Whether you’re welding automotive panels, building structures, or repairing equipment, the right gas can mean the difference between a clean weld and a costly mistake.