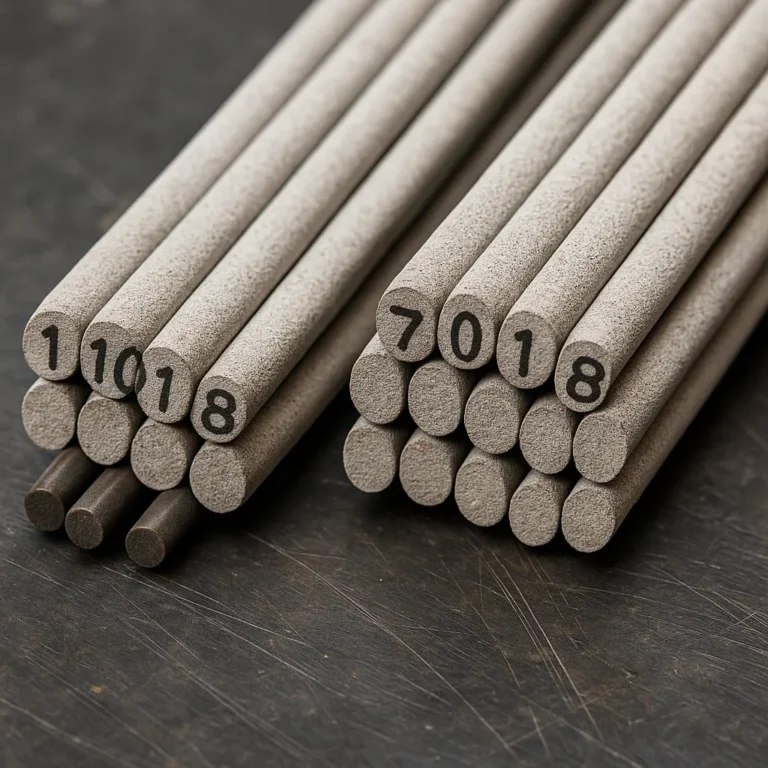

What 7018 Welding Rod Really Means (And Why It Matters)

The 7018 welding rod is a staple in the welding world—well-known for its strength, clean welds, and low-hydrogen properties. Whether you’re patching up a rusty trailer or working on structural beams, this rod comes up again and again as a reliable choice. Let’s break down what those four digits actually mean and how this rod…