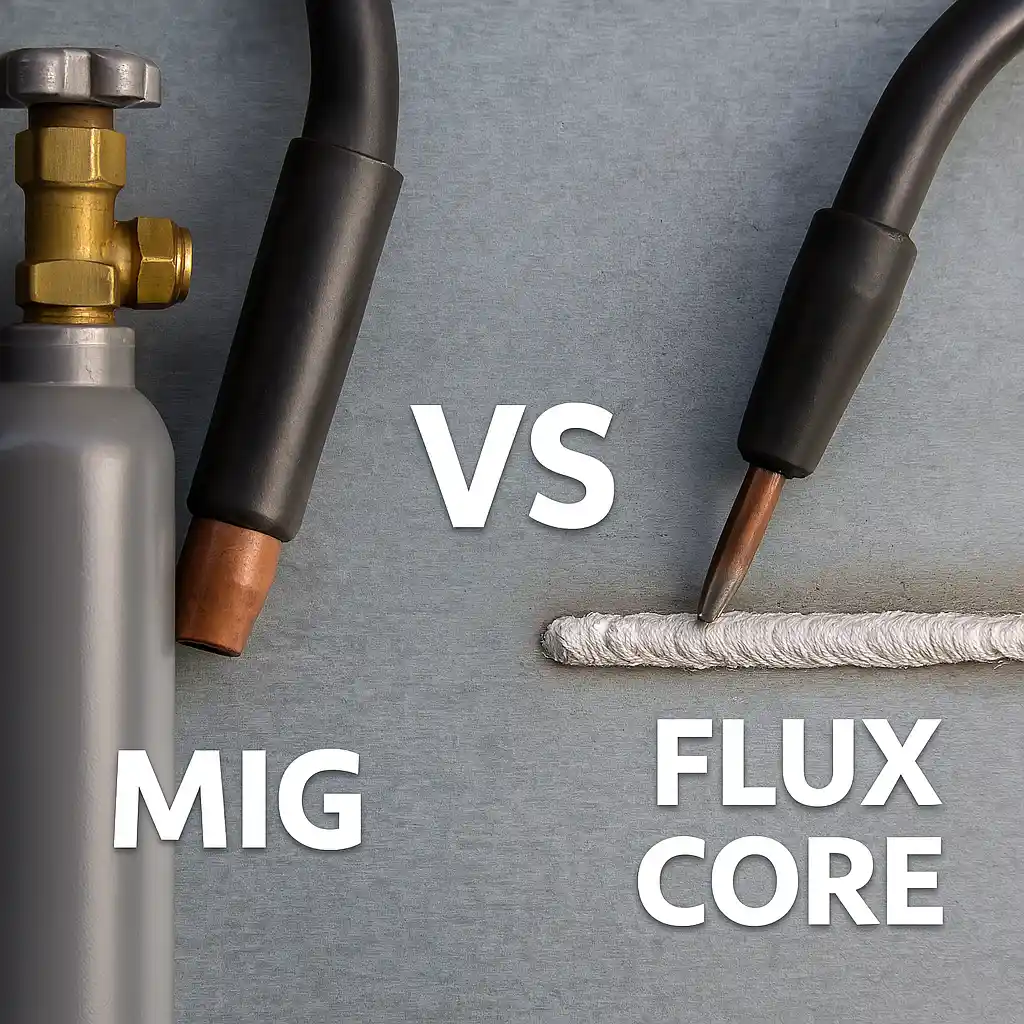

MIG vs Flux Core Welding: Choosing the Right Process for Your Needs

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Welding is a foundational skill in metalwork, and for beginners and professionals alike, understanding the difference between MIG and flux core welding is essential. Each method has its own advantages, ideal use cases, and limitations. Choosing the right one can influence your project outcomes, welding efficiency, and long-term satisfaction with your gear.

Understanding the Basics

MIG (Metal Inert Gas) welding and flux core welding both fall under the broader category of wire-feed welding. However, they operate quite differently. MIG welding uses a shielding gas to protect the weld pool from contamination. Flux core, on the other hand, relies on a flux-filled wire that creates a gas shield during the welding process, eliminating the need for an external tank.

Equipment and Setup Differences

With MIG welding, you need a constant supply of shielding gas—typically a mix of argon and CO₂—which requires purchasing and maintaining a gas cylinder. This setup can be more complex and less portable.

Flux core welders are generally more compact and require less setup time. They are also ideal for outdoor use where wind might blow away shielding gas, which would compromise a MIG weld.

Weld Appearance and Strength

MIG welding typically produces cleaner, more aesthetically pleasing welds with less spatter, making it ideal for automotive work, sheet metal, and projects where appearance matters.

Flux core welding, while powerful, can be messier and require post-weld cleanup due to slag. However, it provides deeper penetration and performs better on dirty or rusted metal—useful for structural work or fabrication in rugged conditions.

Learning Curve and Ease of Use

Beginners may find flux core welding slightly easier to learn, as it requires fewer accessories and is more forgiving of materials that are not perfectly clean.

MIG welding can offer more control and precision, but mastering it requires a bit more finesse in setting gas flow and maintaining proper distance and angle.

Cost Considerations

Flux core welding setups are usually less expensive upfront because they don’t require a gas cylinder or regulator. Wire is readily available and affordable.

MIG welding machines tend to be more expensive due to the need for additional components. Over time, the cost of gas refills should also be considered.

Best Use Cases for Each Method

MIG Welding is best for:

- Automotive bodywork

- Indoor metal fabrication

- Welding thinner metals

- Clean metal surfaces

Flux Core Welding is ideal for:

- Outdoor welding projects

- Heavy-duty construction

- Welding dirty, painted, or rusty metals

- Thicker material and structural joints

Conclusion

Both MIG and flux core welding offer unique benefits. The best choice depends on your work environment, materials, and welding goals. For beginners, a flux core welder provides a budget-friendly, portable start. For precision and cleaner welds, especially in controlled environments, MIG is a solid investment. Understanding the differences will help you build skills effectively and tackle welding projects with confidence.