How to Weld Cast Iron With a MIG Welder Without Cracking It

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Welding cast iron is notoriously tricky due to its high carbon content and brittleness, but with the right preparation and technique, MIG welding can be a viable option. While TIG or stick welding are traditionally used, a MIG welder with the proper setup can repair cast iron effectively—if you follow a careful process.

Why Welding Cast Iron Is Challenging

Cast iron contains graphite flakes or nodules that can make the material brittle when heated and cooled rapidly. When you weld it, the sudden temperature changes and carbon migration can lead to cracking or weak welds. That’s why successful welding of cast iron requires a controlled approach and appropriate filler material.

Choosing the Right MIG Setup

Wire Selection

To weld cast iron with a MIG welder, you’ll need a specialized wire. The best option is nickel-based wire, such as ERNiFe-CI or ENi-CI, designed specifically for cast iron. These wires reduce the risk of cracking and ensure better fusion. A cheaper alternative is mild steel wire (ER70S-6), but it’s only suitable for non-critical applications and may increase the risk of post-weld fractures.

Shielding Gas

Use a 100% argon or 75/25 Argon-CO₂ mix depending on your wire. Nickel wire generally works best with straight argon to maintain arc stability and cleaner welds.

Machine Settings

Set your voltage and wire speed based on the wire manufacturer’s recommendations, and always weld in short-circuit transfer mode. This helps limit heat input, which is crucial to avoid thermal shock in cast iron.

Preparing the Cast Iron for Welding

Proper preparation is essential. Begin by thoroughly cleaning the crack or damaged area—remove oil, grease, paint, and any surface rust. Cast iron is porous and often absorbs contaminants, so thorough cleaning with a grinder and a degreaser is necessary.

If possible, preheat the cast iron to around 400°F to 600°F. This reduces thermal stress during welding. You can use an oven, torch, or induction heater for this step. For small repairs where preheating isn’t possible, keep welds short and allow time to cool between passes.

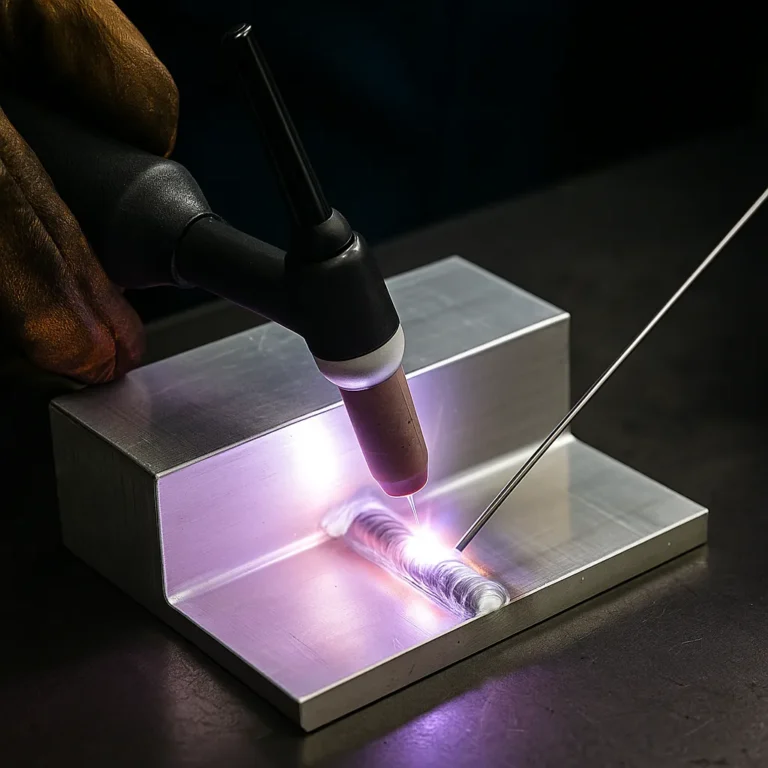

Welding Technique for Cast Iron

Use Short Welds

Apply short weld beads—about 1 inch or less—then pause to allow partial cooling. This helps control expansion and contraction that can cause cracks.

Peen the Weld

After each weld pass, lightly peen the bead using a ball-peen hammer. This relieves stress and helps reduce cracking.

Post-Weld Cooling

Once finished, cool the part slowly. Wrap it in a welding blanket, bury it in dry sand, or place it in an insulated container to prevent sudden temperature drops that can cause stress fractures.

When Not to MIG Weld Cast Iron

Avoid MIG welding if the cast iron part is load-bearing, under constant vibration, or subject to high heat after the repair. In these cases, stick welding with nickel rods or brazing may be more reliable for long-term strength.

Conclusion

Welding cast iron with a MIG welder is possible, but it requires careful prep, the right wire, and precise control of heat input. If you’re repairing non-structural components and take your time, MIG can be a fast and clean solution. However, for high-stress parts, consider alternative methods or professional help.