How Does Laser Beam Welding Work: A Practical Guide

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Laser welding might sound high-tech—and it is—but it’s also becoming a super practical tool for welders who want fast, clean results. Whether you’re working in a fabrication shop or tinkering in your garage, these machines can seriously upgrade your workflow.

What’s Actually Happening When You Laser Weld?

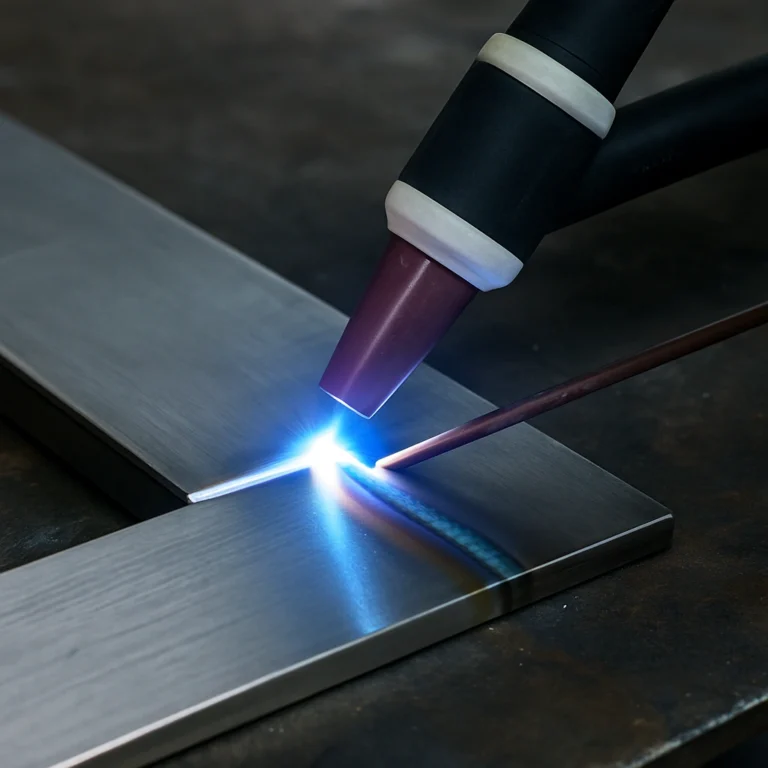

A laser welding machine uses a concentrated beam—usually from a fiber or diode laser—to heat and melt metal at a very precise point. The laser creates a tiny, focused weld puddle that joins metal parts together with minimal heat spread or distortion.

This focused energy means less warping, fewer touch-ups, and a much cleaner overall weld. Laser welders are ideal for working with stainless steel, aluminum, and even dissimilar metals that are harder to join using traditional methods. Some models allow you to use filler wire when needed, but many welds can be done without it.

Real-World Setup: Easier Than Expected

Many modern handheld laser welders are designed to be plug-and-play. Units like the OMTech and Triumph come with a built-in chiller, wire feeder, and laser gun—all you need to get started. As long as you’ve got a 220V power supply and proper safety gear, you’re in business.

There’s no complex gas setup or electrode tuning like in TIG or stick welding. That makes the laser welding process much more approachable, especially for small-shop welders or beginners. According to welder forums and user feedback, many people are producing clean welds after just a few practice sessions.

Where Laser Welders Really Shine

Laser welding is a go-to method when precision, speed, and a clean finish matter. It’s a great fit for:

- Thin stainless steel

- HVAC or auto body aluminum parts

- Galvanized sheet metal

- Decorative or structural welding where seams are visible

For example, small fabrication shops often use laser welders for stainless steel cabinets or metal furniture. You get strong joints with little to no grinding afterward—saving both time and material.

Safety and Maintenance Tips

Because you’re dealing with high-powered light, laser safety goggles are a must. You’ll also want proper ventilation and shielding if you’re working in a shared or open space. Most machines include safety features like interlocks, but don’t skip protective gear.

Fiber lasers are fairly low-maintenance compared to other equipment. Just keep the lens clean, refill the chiller as needed, and follow your machine’s care schedule. There are no tips to change or slag to remove, which means more time welding and less time fixing gear.

Conclusion

Laser welding machines offer a fast, clean, and efficient way to join metal—especially thin or delicate materials. They’re easier to set up than you might expect and can save a ton of time if you’re doing detailed or high-volume work. While they do require an upfront investment, the payoff is solid for fabricators, repair shops, and DIYers looking to boost speed and weld quality without the learning curve of TIG.