Best Welding Rod for Mild Steel: Top Choices Explained

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

When it comes to welding mild steel, the rod you choose can make or break your weld quality. Whether you’re working in your garage, tackling structural repairs, or fabricating new parts, having the right rod helps ensure stronger bonds, cleaner welds, and fewer headaches.

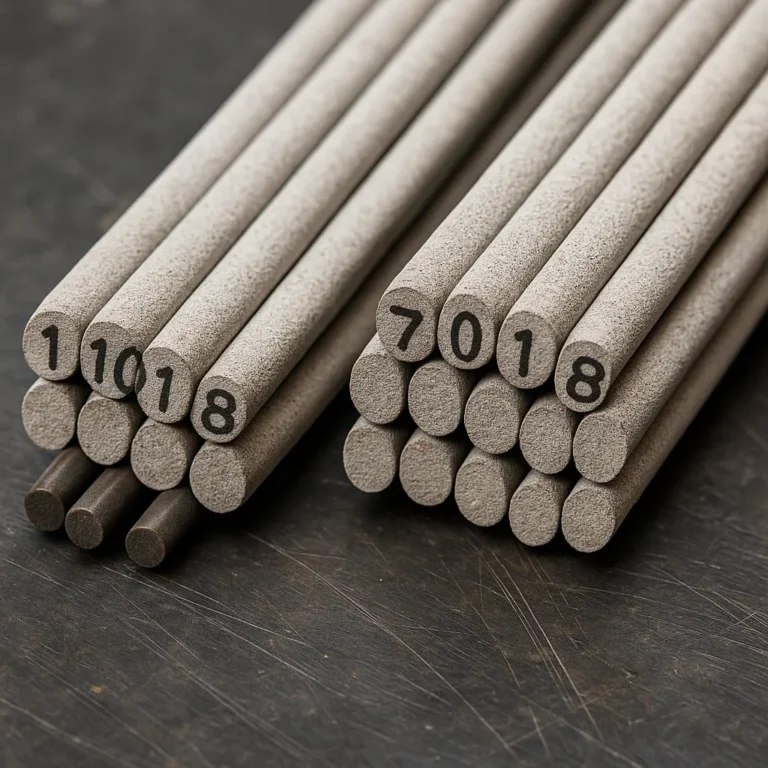

Welding mild steel isn’t complicated—when you’ve got the right rod. A solid welding rod means cleaner welds, fewer restarts, and way less grinding. For most jobs, E7018 and ER70S-6 are the two rods you’ll want in your kit. They’re widely used, beginner-friendly, and they deliver reliable performance without costing a fortune.

Why So Many Welders Trust E7018

E7018 is one of the most dependable choices for stick welding mild steel. It’s low hydrogen, burns smooth, and lays down strong welds that hold up under pressure. Welders consistently recommend it for everything from structural frames to heavy-duty fabrication.

Based on real-world feedback and community forums, this rod runs best on DC reverse polarity and thrives with a steady arc. If you’ve got a decent machine and clean base metal, you’ll likely get a clean bead with minimal spatter.

What About Thinner Steel or Smaller Machines?

For lighter work or compact stick welders, 3/32″ E7018 is a better fit. It handles lower amperage well and gives you control when welding thinner steel.

Plenty of hobby welders use it for projects like angle iron shelves, gate repairs, and general shop work. The arc starts are predictable, and the bead is tight without being overly aggressive—which is exactly what you want on light material.

Prefer TIG? Go with ER70S-6

If TIG is your preferred process, ER70S-6 filler rod is the standard for mild steel. It’s copper-coated for smooth feeding and produces precise, slag-free welds when your base metal is clean.

Metal fabricators and builders rely on ER70S-6 for everything from brackets and frames to custom parts and roll cages. With the right prep and a steady hand, it gives you strong, visually clean welds you won’t have to dress up much afterward.

Check Price & Availability

Here are a few highly rated rods for mild steel welding:

View on Amazon – STARTECHWELD E7018 3/16″ Stick Rod (5LB, Low Hydrogen)

View on Amazon – YESWELDER E7018 3/32″ Stick Rod (5LB, Low Hydrogen)

View on Amazon – TOOLIOM ER70S-6 TIG Rod 3/32″ (5LB, Mild Steel Filler)

Conclusion

E7018 and ER70S-6 are proven, versatile options for welding mild steel. Whether you’re running stick or TIG, working on heavy frames or thinner stock, these rods are trusted for a reason. E7018 gives you solid penetration and arc stability, while ER70S-6 is perfect for clean, detailed TIG welds.

Here’s a quick breakdown:

- E7018 (3/16″) – Great for structural welds and thick metal

- E7018 (3/32″) – Ideal for lighter shop projects and home repairs

- ER70S-6 – Best for TIG welding clean, smooth beads on mild steel

Stick with the one that fits your setup, and you’ll see better welds right away.