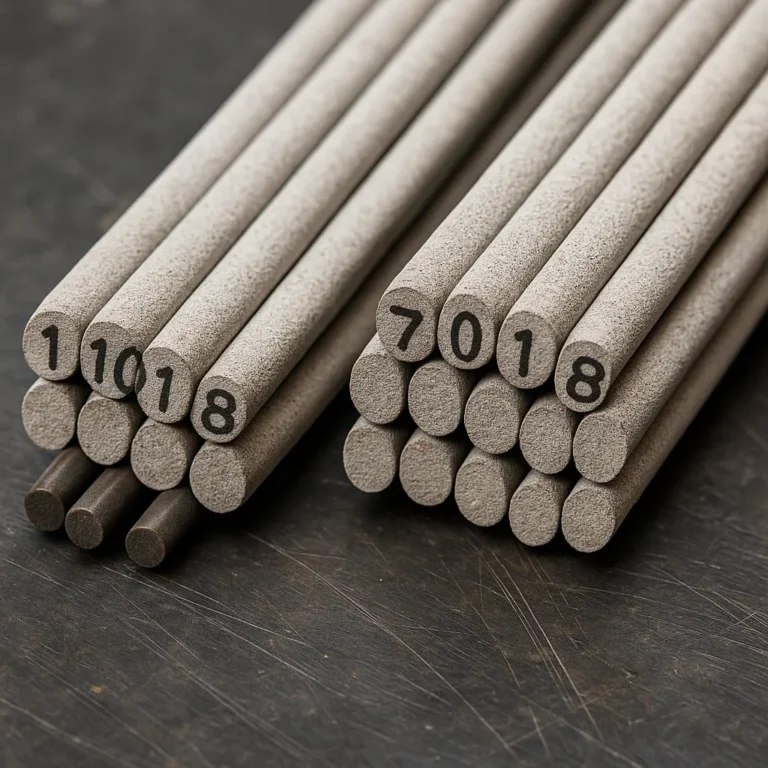

Best Amperage for 7018 Welding Rod: Fine-Tune Your Settings for Cleaner Welds

Getting your amperage dialed in can make or break your weld—especially when you’re working with 7018 rods. These low-hydrogen electrodes are a staple in structural work, fabrication, and general-purpose stick welding. But they only perform at their best when the amps are just right. Let’s break down the best amp ranges for different rod sizes,…