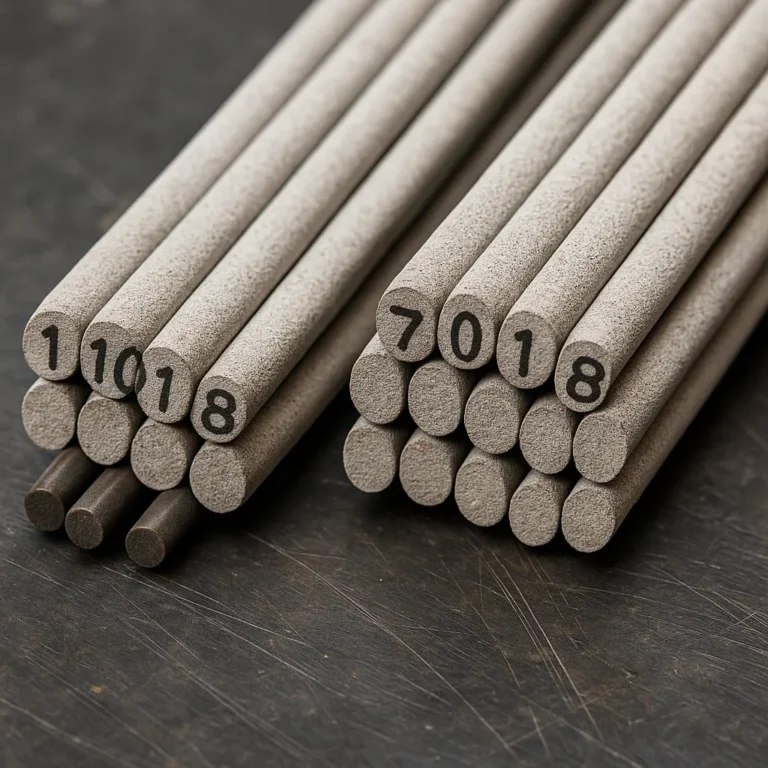

9018 vs 7018 Welding Rods: Choosing the Right One for Strength and Simplicity

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

If you’re working on structural welding or pressure-rated joints, choosing the right low-hydrogen rod matters. While both 7018 and 9018 are strong and dependable, they aren’t interchangeable in every scenario.

Let’s break down what makes these two rods different and when to reach for one over the other.

Arc Performance Is Smooth with Both

Welders who’ve used both say 9018 runs a lot like 7018. You’ll get smooth arcs, stable puddle control, and minimal spatter either way. For anyone already comfortable with 7018, switching to 9018 won’t feel like a big leap.

According to welding forums and fabrication pros, both rods restart well and lay clean, consistent beads. The difference? 9018 just has a bit more bite when you’re welding thicker or more demanding materials.

Strength and Alloys Set 9018 Apart

Here’s where things start to diverge. 7018 offers about 70,000 psi in tensile strength—plenty for general structural welding and everyday jobs. But 9018 bumps that number higher, often into the 90,000+ psi range.

That extra strength comes from added alloying elements like molybdenum or chromium. It’s why 9018 is often used in high-pressure systems, heavy steel fabrication, and industrial-grade pipework.

Equipment and Handling Considerations

Both 7018 and 9018 can be run on AC or DC+, so they’re compatible with most stick welders. But 9018 tends to be more sensitive to moisture. If you’re working in humid environments or don’t have a rod oven, this can be a deal-breaker.

7018 still benefits from dry storage, but it’s more forgiving overall. It’s easier to work with in smaller home shops or in the field where conditions aren’t always perfect.

Which One Fits Your Work?

If you’re handling mild steel, farm equipment, or general-purpose welding, 7018 is probably all you need. It’s easy to use, relatively low-maintenance, and delivers clean welds with solid strength.

On the other hand, 9018 shines in critical applications—like pressure vessels, high-temperature equipment, or thick, alloyed steel. It costs a bit more and demands better storage and prep, but the performance boost is worth it for heavy-duty work.

Conclusion

Both 7018 and 9018 are solid low-hydrogen electrodes, but they’re built for different types of welding. Choose 7018 if you need a reliable, easy-to-use rod for general work. Go with 9018 when your job calls for higher tensile strength, added alloy performance, and stricter structural standards. The right choice comes down to what you’re welding—and how much you’re willing to prep for it.