Can You Use CO₂ for TIG Welding: What Every Welder Should Know

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

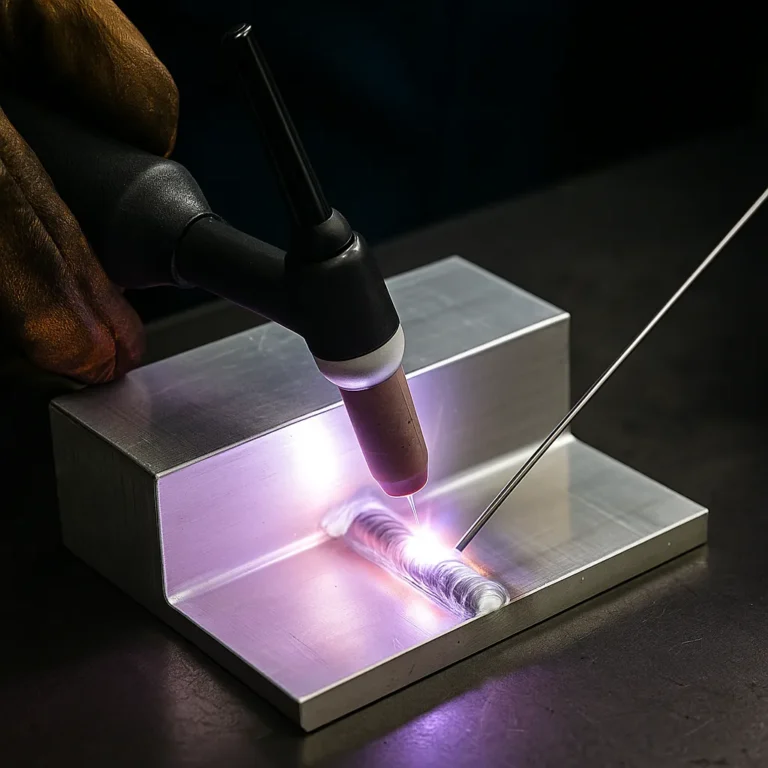

TIG welding is known for its precision and clean welds, often used in projects requiring superior aesthetic and structural quality. While argon is the industry-standard shielding gas, some welders ask whether CO₂ can be a substitute. It’s a fair question, especially when cost and availability are considered. However, TIG welding and CO₂ generally don’t mix well—and here’s why.

Why Shielding Gas Matters in TIG Welding

Shielding gas protects the weld puddle from atmospheric contamination. In TIG welding, this is especially critical due to the absence of flux or filler material in some cases. Pure argon, or a mix of argon and helium, is commonly used because these inert gases don’t react with the molten metal. The result is a smooth, strong, and clean weld.

Carbon dioxide, by contrast, is an active gas. In MIG welding, CO₂ enhances penetration and works well with flux-cored wire. But when used in TIG welding, it introduces oxidation, arc instability, and excess spatter—qualities that undermine everything TIG stands for.

Can You Use CO₂ for TIG Welding?

Technically, yes—you can flow CO₂ through a TIG torch. Practically, no—you shouldn’t. CO₂ reacts with the high temperatures in TIG welding, leading to contamination and inferior weld quality. The tungsten electrode, a cornerstone of TIG welding, is particularly vulnerable to degradation when exposed to reactive gases like CO₂. Expect erratic arcs, sputtering, and an increased risk of porosity.

In some rare experimental setups, controlled CO₂ usage has been tested with specific metals and techniques. However, these are the exceptions, not the rule. For everyday welders, the trade-offs aren’t worth it.

What Happens If You Try It Anyway?

Using CO₂ in TIG welding will likely result in:

- Oxidized and porous welds

- Rapid tungsten electrode deterioration

- Unstable arc performance

- Increased spatter

- Risk of weld failure in structural applications

Even when welding steel—where CO₂ is often favored in MIG—TIG demands a more inert atmosphere. Substituting argon with CO₂ will leave you battling against the core principles of the TIG process.

Better Alternatives to CO₂

If argon is unavailable or costly, consider these alternatives:

- Argon-Helium Mix: Increases heat input, suitable for thicker materials.

- Argon-Hydrogen Mix: Occasionally used in stainless steel TIG for deeper penetration, but only in controlled conditions.

- Straight Helium: Great for deeper penetration but harder to start and more expensive.

While these gases also come at a cost, they preserve the integrity of TIG welding far better than CO₂.

Conclusion

CO₂ may be a workhorse in MIG welding, but in the precise world of TIG, it falls short. Using CO₂ as a shielding gas in TIG welding leads to contamination, instability, and inferior results. If you’re aiming for quality welds—especially on stainless steel, aluminum, or any high-spec job—stick to argon or its recommended alternatives. TIG welding’s precision deserves the right tools and conditions.