Vulcan ProTIG 165 Review: Reliable TIG Performance in a Compact Frame

The Vulcan ProTIG 165 has gained attention as a capable and affordable TIG welder for hobbyists, DIY welders, and light fabrication professionals. With dual voltage input, portability, and a simple control interface, it positions itself as a solid option for those seeking quality results without investing in high-end equipment. In this review, we dive into its key features, real-world usability, and what sets it apart in the competitive TIG welder market.

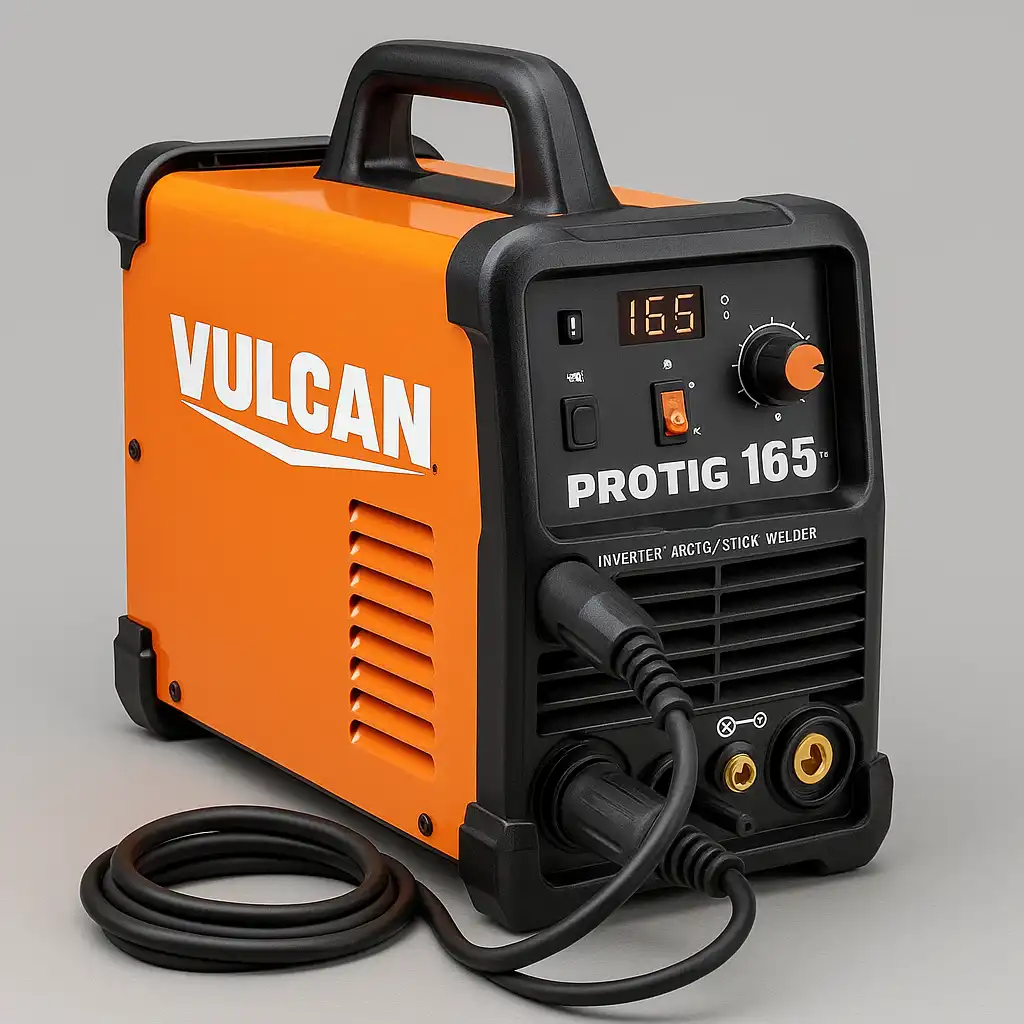

Vulcan ProTIG 165 Review

Design and Build Quality

The Vulcan ProTIG 165 is housed in a lightweight yet rugged casing that makes it highly portable. Weighing just under 21 pounds, it’s easy to transport from shop to job site. Its digital display and clearly marked control knobs make adjustments intuitive, even for beginners. The 120/240V dual-voltage input enhances flexibility, especially for those working in a variety of environments.

Performance and Power Output

This TIG welder is capable of welding steel, stainless, and thinner gauge metals with precision. With a maximum output of 165 amps and a duty cycle of 25% at 165A on 240V, it performs admirably for its class. Arc starts are consistently smooth thanks to high-frequency (HF) start, which minimizes contamination and improves control at the start of the weld. On DC TIG, it handles carbon steel with finesse, producing clean, smooth beads.

For those looking to weld aluminum, it’s important to note that the Vulcan ProTIG 165 is DC-only, so it’s not suited for aluminum TIG welding out of the box.

Ease of Use and Features

One standout feature is its user-friendly interface. The digital readout allows for precise amperage control, while the HF start and infinite amperage adjustment make dialing in the correct settings straightforward. It also includes a foot pedal input (though not bundled) for better control during longer or more complex welds.

For stick welding, the ProTIG 165 performs surprisingly well, making it a true dual-process machine. It’s ideal for quick jobs that don’t require the finesse of TIG.

Who Is It Best For?

The Vulcan ProTIG 165 is best suited for:

- Hobbyists or weekend welders looking for quality without overpaying

- Auto repair and sheet metal fabrication

- On-the-go professionals who value portability

- Welding students needing a reliable entry-level TIG machine

It’s not intended for heavy-duty or industrial aluminum TIG welding due to its lack of AC output.

Conclusion

The Vulcan ProTIG 165 delivers where it counts: lightweight portability, strong TIG performance on steel, and a simple, no-frills user experience. While it’s limited to DC TIG, it remains one of the most compelling options for welders needing mobility and clean welds on mild steel or stainless. For its price point and capability, it’s a tool that earns its place in any small welding setup.