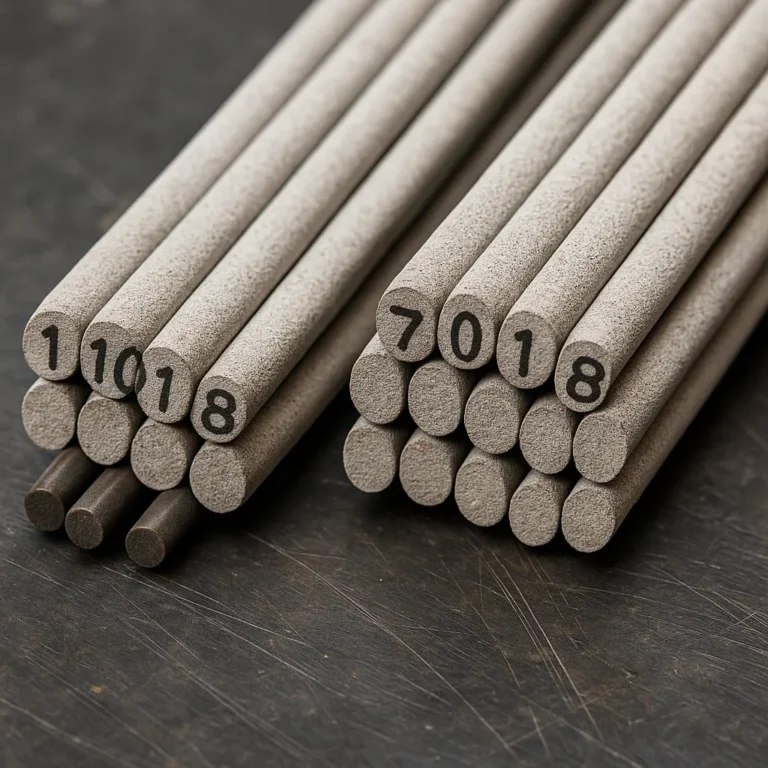

11018 Welding Rod vs 7018: Strength, Usability, and When to Use Each

When it comes to structural stick welding, choosing the right rod isn’t just about preference—it’s about performance. Two of the most commonly compared options are 11018 and 7018. Both are low-hydrogen electrodes, but they serve different purposes depending on your project’s demands. Whether you’re building a gate, repairing heavy equipment, or welding high-strength steel, the…