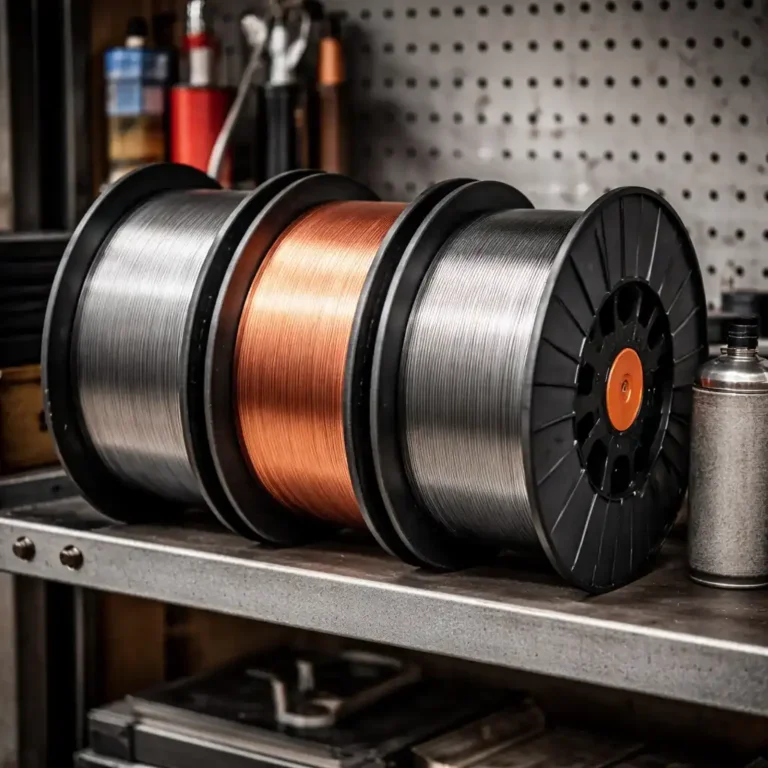

How to Keep Welding Wire From Rusting: Storage Tips, Shop Setup, and Moisture Control

Last Updated: December 2025 Rusty welding wire causes issues long before you ever strike an arc. Even light surface corrosion can lead to rough wire feeding, unstable arcs, extra spatter, and contaminated welds. Whether you’re welding occasionally in a home garage or running wire daily in a fabrication shop, keeping moisture away from your wire…