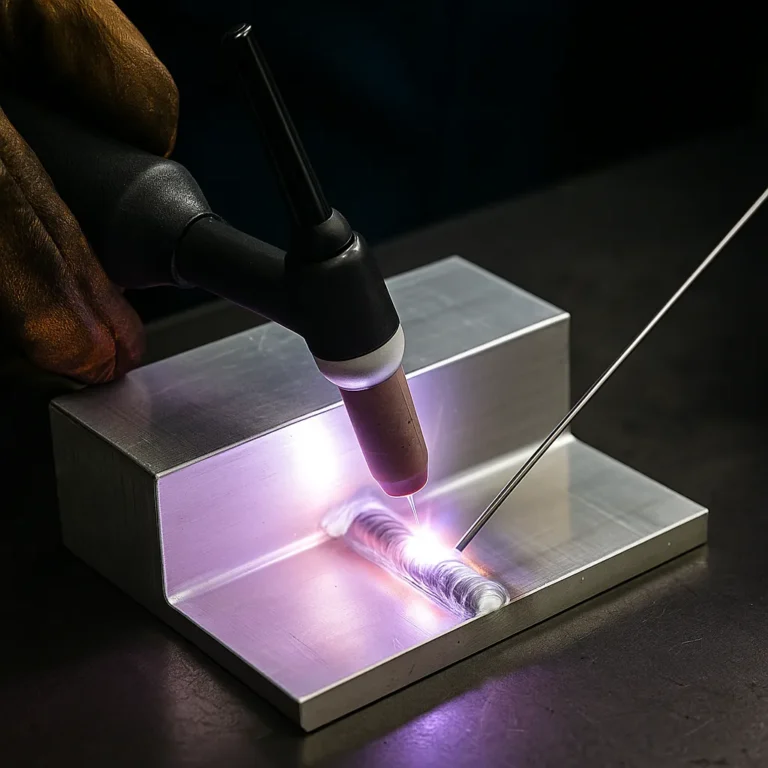

Can You TIG Weld Aluminum with DC Current? Tips That Actually Work

If you’ve only got a DC TIG machine and need to weld aluminum, you’re not out of luck—but you’re in for a bit of a challenge. While aluminum is typically welded using AC current, it is possible to do it with DC. You just have to know what you’re working with, prep properly, and adjust…