How to Keep Welding Wire From Rusting: Storage Tips, Shop Setup, and Moisture Control

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Last Updated: December 2025

Rusty welding wire causes issues long before you ever strike an arc. Even light surface corrosion can lead to rough wire feeding, unstable arcs, extra spatter, and contaminated welds. Whether you’re welding occasionally in a home garage or running wire daily in a fabrication shop, keeping moisture away from your wire is key to consistent results.

👉 If you’re dialing in your shop setup piece by piece, this breakdown of essential welding consumables every shop should keep on hand explains how wire, gas, and supporting accessories all work together to protect weld quality and equipment.

Knowing how to keep welding wire from rusting comes down to storage habits, humidity control, and reducing unnecessary exposure between welding sessions.

🔍 Why Welding Wire Rusts So Easily

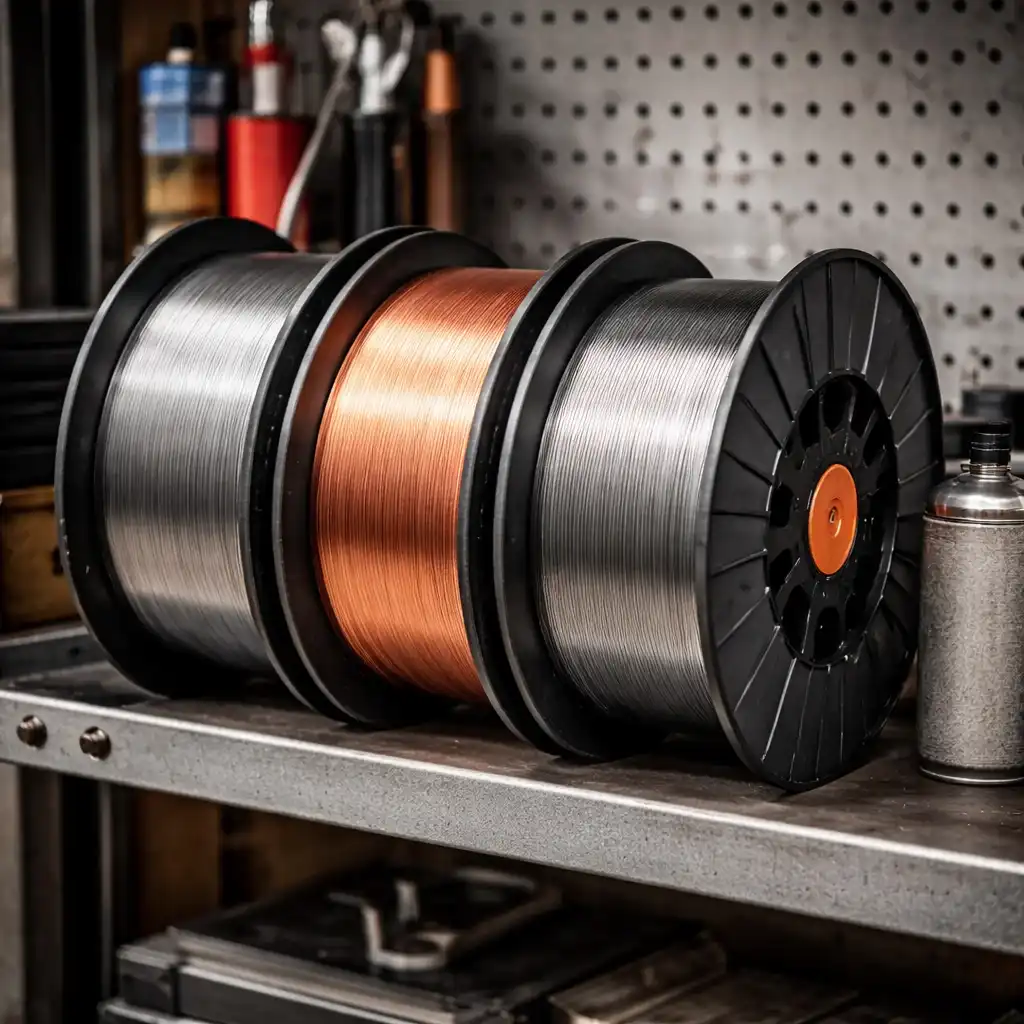

Most welding wire is bare steel or lightly copper-coated, which makes it highly sensitive to moisture in the air. Humidity, temperature swings, and condensation are the biggest contributors—especially in garages, sheds, or shops without climate control.

Once a spool is opened, moisture in the air can settle directly on the wire surface. Over time, that exposure leads to oxidation that affects both feeding performance and weld consistency.

🔍 Store Welding Wire in a Dry, Controlled Environment

The most effective way to prevent rust is storing welding wire in a dry, stable environment. Indoor storage is always better than unheated garages or outdoor sheds where temperatures fluctuate.

Keeping wire off concrete floors and away from exterior walls also helps. These areas tend to stay cooler and collect moisture, increasing the risk of condensation forming on the wire.

🔍 Use Sealed Containers and Storage Solutions

Sealed storage adds an extra layer of protection, especially for spare or infrequently used spools. Airtight bins, dedicated wire cabinets, and storage tubes all help isolate wire from humidity and shop dust.

Adding desiccant packs inside containers is a simple but effective step. They absorb moisture inside the container and can significantly extend the usable life of your wire.

🔍 Protect Wire While It’s on the Welder

Rust doesn’t only happen in storage. Wire can also corrode while mounted on the machine if it’s left exposed between welding sessions.

Using spool covers, storing the welder in a dry area, or removing wire when it’s not in use helps reduce surface corrosion. In higher-humidity shops, wire cleaning systems can also help limit rust and improve feeding consistency.

🔍 Control Humidity in Your Shop

Humidity control plays a major role in keeping welding wire usable. In damp climates or basement shops, a dehumidifier can make a noticeable difference—not just for wire, but for machines and tools as well.

Even improving airflow and ventilation helps prevent moisture from lingering around consumables.

🔍 Handle Welding Wire With Clean Hands

Oil, sweat, and grime transferred from hands can speed up corrosion on wire surfaces. While it seems minor, frequent handling without gloves can introduce moisture and contaminants over time.

Using gloves or handling wire with clean, dry hands helps preserve wire condition, especially in humid environments.

🔍 When to Replace Rusty Welding Wire

Light discoloration may still allow wire to feed, but heavily rusted wire usually causes more trouble than it’s worth. Feeding issues, liner wear, arc instability, and weld defects often follow.

If rust flakes are visible or the wire feeds inconsistently, replacing the spool is usually the safest and most efficient option.

📌 Key Takeaways

- Welding wire rusts quickly when exposed to humidity and condensation

- Dry indoor storage greatly reduces corrosion risk

- Sealed containers and desiccant packs extend wire lifespan

- Wire can rust even while mounted on the welder

- Humidity control protects wire, machines, and tools

- Heavily rusted wire is best replaced, not reused

🟢 FAQs

Q: Can you weld with slightly rusted MIG wire?

Light surface rust may still weld, but it often causes spatter, arc instability, and inconsistent bead appearance.

Q: Does copper-coated welding wire rust?

Copper coating slows corrosion, but it does not prevent rust if the wire is exposed to moisture.

Q: Should welding wire be stored in sealed containers?

Yes. Sealed containers with desiccant packs provide excellent protection against humidity and rust.

Q: How long does welding wire last if stored properly?

When kept dry and sealed, welding wire can remain usable for years without significant corrosion.

✅ Conclusion

Keeping welding wire from rusting comes down to moisture control, smart storage, and limiting exposure between welding sessions. Dry environments, sealed containers, humidity management, and basic handling habits all help preserve wire quality. Taking these steps upfront saves time, reduces weld defects, and keeps your equipment feeding smoothly.