Can You Weld Cast Iron to Steel and Get Strong Results?

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Welding cast iron to steel is absolutely doable, but it’s not the kind of job you want to rush into. These two metals behave very differently when heated, and unless you prep properly and use the right filler, your weld could crack—or completely fail—after cooling.

If you’re tackling a repair that involves joining cast iron and steel, here’s what you need to know before striking an arc.

Why Cast Iron and Steel Don’t Naturally Get Along

Cast iron is brittle and full of carbon. Steel, on the other hand, is more flexible and holds up better under stress. The trouble starts when heat hits both metals during welding. Cast iron tends to expand and contract unpredictably, which leads to cracking—especially if it cools too fast.

Welders who’ve done this type of repair say that nickel-based filler rods like ENiFe-CI or ENi-CI work best. MIG can be used in some cases, but it comes with more risk of weld failure unless your settings and prep are dialed in tight.

What Fillers and Welding Processes Actually Work

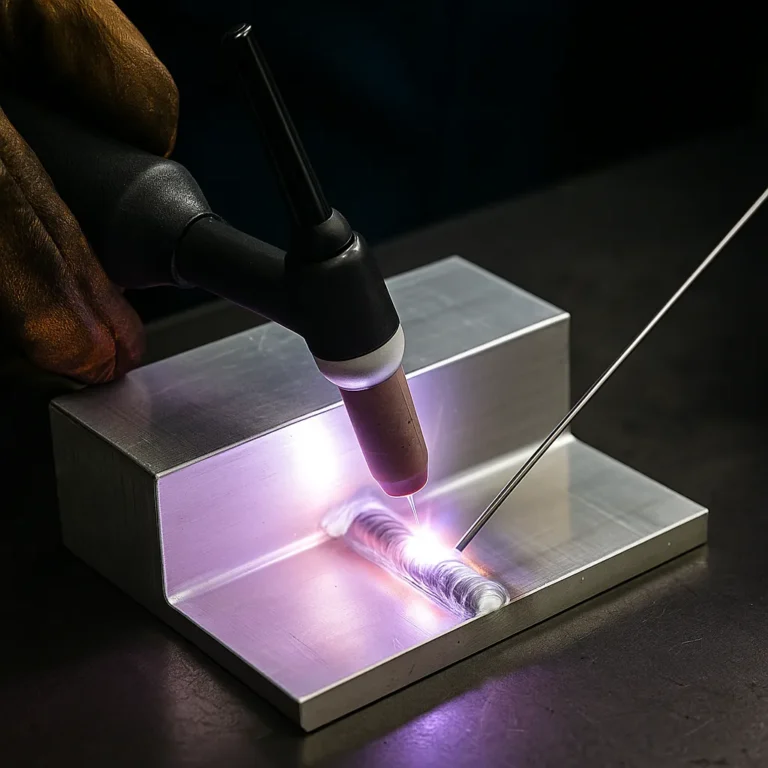

Stick and TIG welding are the most trusted processes for joining cast iron to steel. They offer better control and deeper penetration than MIG, especially when working with dirty or uneven surfaces.

Recommended filler choices include:

- ENiFe-CI (nickel-iron) rods

- ENi-CI (pure nickel) rods

- 99Ni wire for TIG or MIG

- 309L stainless rods (use with caution—prone to cracking if cooling isn’t managed well)

Most small-shop welders report that TIG with a nickel filler gives the cleanest, most consistent results. Stick welding is great for outdoor work or castings that aren’t super clean or easy to fixture.

Setup Tips: Preheat, Peening, and Cooling Right

Getting this kind of weld to hold isn’t just about the arc—it’s all about prep. You need to preheat the cast iron to reduce the thermal shock that causes stress and cracks. A good target is around 500°F, which you can hit using a rosebud torch or an oven.

Once you’re done welding, the slow cool-down is just as important. Wrap the part in a welding blanket, bury it in dry sand, or even let it sit overnight in an insulated container to avoid rapid cooling.

Many welders also recommend peening the bead right after welding. Lightly tapping the weld with a hammer while it cools can help relieve internal stress and prevent cracking. It might seem old-school, but it’s a trusted technique for cast iron.

When This Comes Up in Real Repairs

Welding cast iron to steel usually happens during unexpected repairs—like fixing a cast iron mount with a steel bracket, or reworking older machinery where parts aren’t easily replaced. It’s not usually part of a clean fabrication project. Instead, it’s the kind of job that shows up in a garage, a farm, or a repair shop when something breaks.

If you’re using a basic DC stick or TIG machine with decent low-amp control, you’re good to go. Just make sure the cast iron is clean, preheated, and cooled properly after the weld.

Plenty of welders say it’s smart to practice on scrap cast iron before jumping into the real deal. Old brake rotors or cracked manifolds make great practice material.

Conclusion

Yes, you can weld cast iron to steel—and get a strong result—as long as you prep correctly. Preheat the cast iron, use a nickel-based filler rod, and let the part cool down slowly after the weld. TIG or stick welding both work well, especially when paired with short weld passes and careful stress management.

This kind of repair is best for welders who have some time, patience, and the right filler. If you’re in a rush or skip the prep, odds are good the weld will crack before the job’s even done cooling.