Best Welding Clamps for Fabrication: Strong Holding Power for Accurate Fit-Up

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Last Updated: December 2025

Good fabrication always starts with solid fit-up. When parts move during tacking or welding, gaps open up, alignment drifts, and distortion becomes harder to control. That’s when you end up fighting the joint instead of focusing on the weld itself. Reliable welding clamps keep material locked in place so joints stay square, flush, and consistent from the first tack to the final pass.

The three welding clamps below cover the most common fabrication needs: heavy-duty holding force for structural work, versatile locking clamps for everyday fabrication, and precision butt clamps for sheet metal and panel welding.

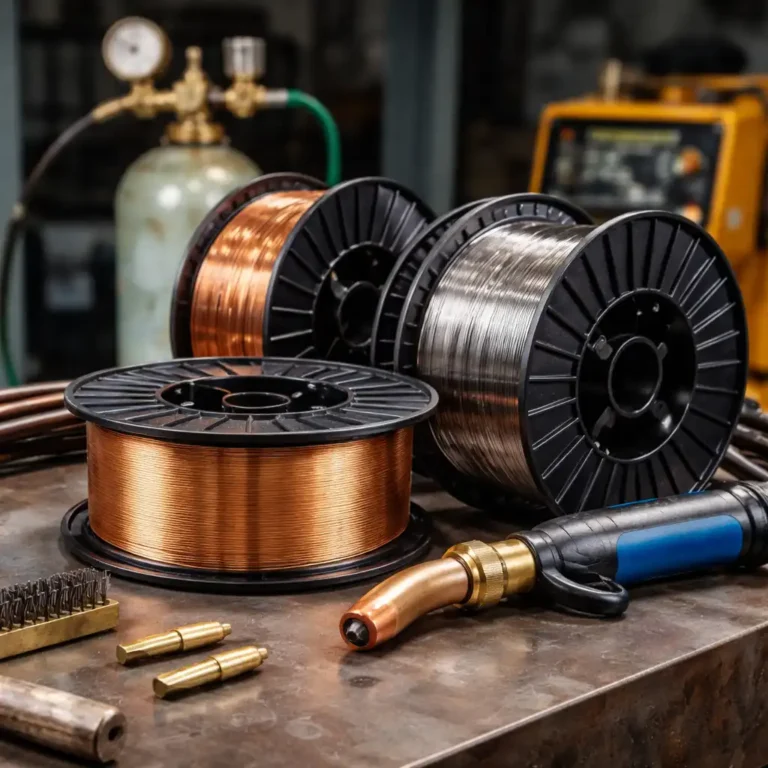

👉 If you’re building out a dependable fabrication setup, this overview of how clamps, magnets, and consumables support proper fit-up breaks down why fixturing tools matter just as much as wire and shielding gas in real shop conditions.

💰 Check Price & Availability

View on Amazon – 12″ Heavy-Duty F-Clamps (4-Pack, 1320 lb Capacity)

View on Amazon – MAXPOWER 11″ Locking C-Clamps (4-Pack)

View on Amazon – Toolly Butt Welding Clamps (16-Pack)

📋 Quick-View Comparison List

Best Overall Holding Power: 12″ Heavy-Duty F-Clamps (4-Pack)

Best Versatile Fabrication Clamp: MAXPOWER Locking C-Clamps

Best Precision Panel Alignment: Toolly Butt Welding Clamps

🔍 Why Welding Clamps Matter in Fabrication

Clamps do more than just hold parts together. They control alignment, manage joint gaps, and help resist movement caused by heat distortion during welding.

In fabrication work—especially with thicker steel or multi-part assemblies—weak or poorly placed clamps lead to shifting joints, uneven welds, and extra grinding or rework later. Strong, well-built clamps make the entire welding process more predictable and far less frustrating.

🔍 Common Types of Welding Clamps Explained

Different fabrication jobs call for different clamp styles:

- F-clamps provide high clamping force with deep reach

- Locking C-clamps allow fast, one-handed operation with adjustable pressure

- Butt welding clamps maintain consistent gaps for edge-to-edge joints

Most fabrication shops keep a mix on hand so they’re not forcing one clamp to do every job.

📦 12″ Heavy-Duty F-Clamps – Best Overall for Fabrication

These heavy-duty F-clamps deliver serious holding power, making them well suited for structural fabrication, thick plate work, and large assemblies. With a 1320 lb load capacity and forged steel construction, they resist flexing even when heat starts pulling the joint.

The 12-inch opening and deep throat depth make it easier to reach past edges and hold material securely where lighter clamps tend to slip or twist under load.

📦 MAXPOWER 11″ Locking C-Clamps – Best for Versatility

MAXPOWER locking C-clamps are a reliable choice for general fabrication and everyday welding tasks. The locking plier design allows quick one-handed clamping, while the adjustable jaw and hex key hole give you extra tightening power when needed.

They’re especially useful for tack welding, temporary fixturing, and jobs where clamps need to be moved and repositioned frequently.

📦 Toolly Butt Welding Clamps – Best for Precision Fit-Up

Toolly butt welding clamps are designed specifically for edge-to-edge welding. They hold panels in alignment while maintaining a consistent gap—typically around 1mm—which helps achieve proper penetration with minimal distortion.

These clamps are commonly used in automotive fabrication, patch panels, and sheet metal work where alignment accuracy matters more than raw clamping force.

🔍 Choosing the Right Welding Clamps for Your Projects

For heavy fabrication and structural work, high-capacity F-clamps are hard to beat. For general shop use, locking C-clamps offer the best balance of speed and flexibility. For thin material and panel welding, dedicated butt clamps save time and improve consistency.

Most fabrication shops rely on a mix of clamp types so they’re ready for different materials, thicknesses, and joint styles without slowing down the job.

📌 Key Takeaways

- Welding clamps control alignment and help limit distortion

- F-clamps provide maximum holding power for heavy fabrication

- Locking C-clamps are fast and versatile for general shop use

- Butt welding clamps maintain consistent gaps for panels

- Proper clamping reduces rework and cleanup time

🟢 FAQs

Q: How many welding clamps should a fabrication shop have?

More than you think. Using multiple clamps allows even pressure and better alignment across assemblies.

Q: Are locking C-clamps strong enough for welding?

Yes, for many tasks. Heavier structural work may still require stronger F-clamps.

Q: Do butt welding clamps work on thick steel?

They’re best suited for sheet metal and thinner materials, not heavy plate.

Q: Can regular woodworking clamps be used for welding?

Some can, but welding-rated clamps handle heat and spatter far better.

✅ Conclusion

The best welding clamps for fabrication depend on the type of work you do most often. Heavy-duty F-clamps provide the strength needed for structural jobs, locking C-clamps offer fast and flexible holding for everyday fabrication, and butt welding clamps deliver precise alignment for panels and sheet metal. Having the right clamps on hand improves fit-up, reduces distortion, and makes fabrication work smoother from start to finish.