Best TIG Filler Rods for Steel and Stainless Steel (Reliable Choices for Clean, Consistent Welds)

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Last Updated: December 2025

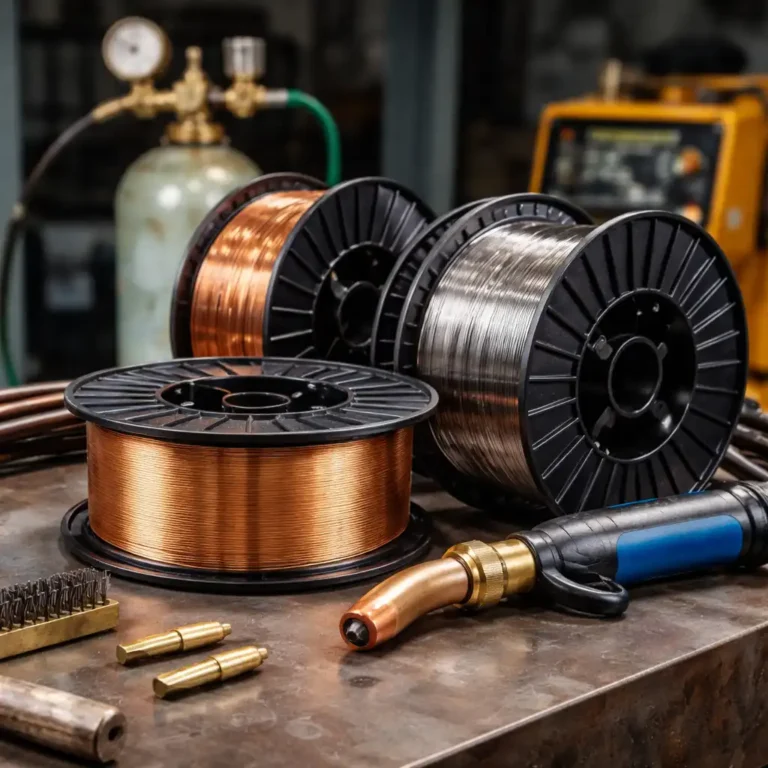

Choosing the right TIG filler rod plays a big role in how controllable your welds feel and how clean the finished bead looks. When the filler doesn’t match the base metal or the job conditions, problems show up fast—poor puddle wetting, contamination, or uneven bead appearance. The right filler rod makes TIG welding smoother, more predictable, and easier to repeat.

The three TIG filler rods below cover the most common steel and stainless steel applications. Each one is chosen for a specific use case: everyday mild steel welding, general stainless work, and tougher situations where surface prep isn’t perfect.

👉 If you’re building a TIG setup from the ground up, this practical breakdown of welding consumables and setup choices explains how filler selection, base metal, and prep all work together.

💰 Check Price & Availability

- View on Amazon – TOOLIOM ER70S-6 TIG Filler Rod (3/32″, 5 lb)

- View on Amazon – YESWELDER ER308L Stainless TIG Filler Rod (3/32″, 5 lb)

- View on Amazon – STARTECHWELD ER70S-2 TIG Filler Rod (1/16″, 2 lb)

📋 Quick-View Comparison List

- Best for Mild / Carbon Steel: TOOLIOM ER70S-6

- Best for Stainless Steel (General Use): YESWELDER ER308L

- Premium Steel Option for Tough Conditions: STARTECHWELD ER70S-2

🔍 Choosing the Right TIG Filler Rod for Steel vs Stainless

TIG filler rods are not interchangeable across materials. Carbon steel and stainless steel require different alloy compositions to maintain strength, corrosion resistance, and crack resistance.

Using the correct filler rod helps the puddle wet out smoothly, keeps dilution under control, and ensures the finished weld maintains its intended mechanical and corrosion properties. Matching filler rod to the base metal matters just as much as amperage, torch angle, and travel speed.

🔍 ER70S-6 vs ER70S-2: Mild Steel TIG Rod Differences

ER70S-6 and ER70S-2 are both common mild steel TIG filler rods, but they behave differently once you strike an arc.

ER70S-6 contains higher levels of silicon and manganese, which helps the puddle tolerate light surface contamination and flow more smoothly. It’s generally the more forgiving option and works well on clean or lightly scaled steel.

ER70S-2 is triple-deoxidized, making it better suited for steel with mill scale, rust, or imperfect surface prep. It’s often preferred for critical welds or situations where cleanup isn’t ideal.

🔍 ER308L: The Standard TIG Rod for Stainless Steel

ER308L is the most commonly used TIG filler rod for stainless steel welding. Its low carbon content helps prevent carbide precipitation, which protects corrosion resistance after welding.

It’s widely used on grades like 304, 304L, and 308L and performs well in everything from general fabrication to food-grade and decorative stainless work. For most stainless TIG applications, ER308L is the safe, dependable choice.

📦 TOOLIOM ER70S-6 TIG Filler Rod (3/32″, 5 lb) – Best for Mild / Carbon Steel

TOOLIOM’s ER70S-6 TIG filler rod is a reliable everyday option for mild steel welding. The copper-coated rods promote smooth arc starts and predictable puddle behavior, which helps maintain consistent bead shape.

It performs well on clean steel and lightly scaled material, making it a solid choice for fabrication, repair work, and general shop projects where consistency matters.

📦 YESWELDER ER308L Stainless TIG Filler Rod (3/32″, 5 lb) – Best for Stainless Steel

YESWELDER’s ER308L TIG filler rod is designed for general-purpose stainless steel welding. The low-carbon formulation supports corrosion resistance while producing clean, uniform welds.

It works well on common stainless grades and suits a wide range of projects, from brackets and tubing to panels and frames.

📦 STARTECHWELD ER70S-2 TIG Filler Rod (1/16″, 2 lb) – Premium Steel Option

STARTECHWELD’s ER70S-2 TIG filler rod is built for more demanding conditions. Its triple-deoxidizer blend helps reduce porosity when welding steel with rust, mill scale, or less-than-perfect prep.

The smaller diameter offers better control on thin material and root passes, making it a strong choice when precision and weld quality matter more than speed.

📌 Key Takeaways

- ER70S-6 is a forgiving, all-around choice for mild steel TIG welding

- ER308L is the standard filler rod for most stainless steel applications

- ER70S-2 performs best when surface prep isn’t ideal

- Matching filler rod to base metal is critical for weld quality

- Rod diameter affects puddle control and heat input

🟢 FAQs

Q: What TIG filler rod should I use for mild steel?

ER70S-6 is the most common and forgiving option, while ER70S-2 is better for dirtier or scaled steel.

Q: What TIG rod is best for stainless steel?

ER308L is the best general-purpose TIG filler rod for most stainless steel welding.

Q: Can the same TIG rod be used for steel and stainless?

No. Using the wrong filler rod can compromise weld strength and corrosion resistance.

Q: Does TIG filler rod diameter matter?

Yes. Smaller diameters offer better control on thin material, while larger rods suit thicker joints.

✅ Conclusion

The best TIG filler rods depend on the material you’re welding and the conditions you’re working in. TOOLIOM ER70S-6 is a dependable choice for everyday mild steel TIG welding, YESWELDER ER308L covers most stainless steel applications, and STARTECHWELD ER70S-2 delivers premium performance when surface prep isn’t perfect. Choosing the right filler rod makes TIG welding cleaner, more controlled, and far more consistent.