Best Welding Consumables: Essential Supplies Every Welder Should Know

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Last Updated: December 2025

Welding machines usually get the attention, but consumables are what decide whether a job goes smoothly or turns into constant troubleshooting. Wire quality, rod condition, gas flow, abrasives, and everyday shop supplies all directly affect bead quality, penetration, and consistency. When consumables are poor or mishandled, even a dependable welder can feel unpredictable.

This hub brings all of our in-depth guides on welding consumables into one place. It’s meant to help you find clear buying advice, real-world usage guidance, and proper storage tips without digging through scattered articles. Whether you’re running MIG, TIG, or Stick, these resources focus on consumables that hold up under heat, spatter, and daily shop use.

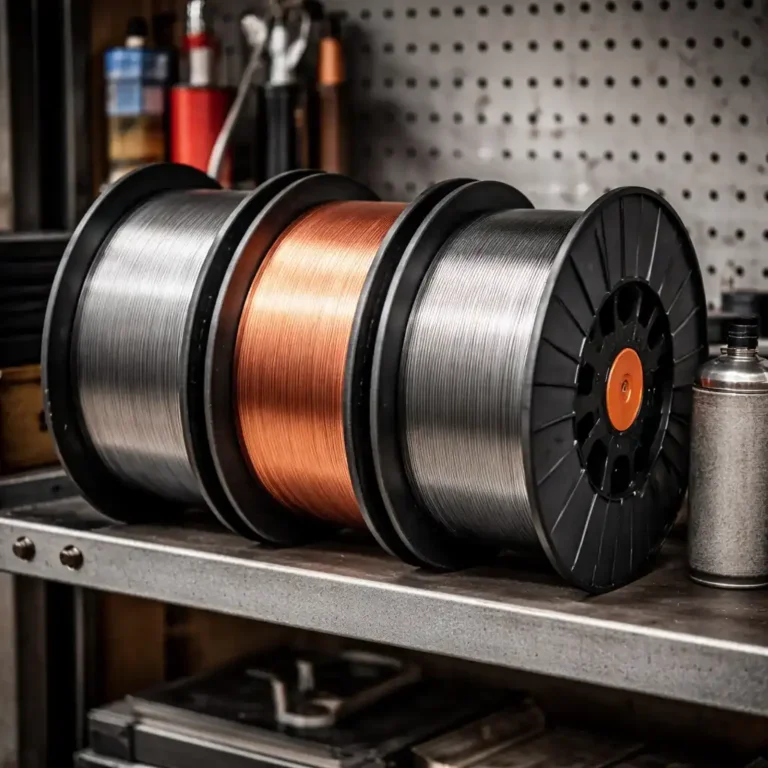

🔍 Welding Wire, Rods & Filler Materials

Wire and filler choice has a bigger impact on weld quality than most welders realize. The wrong wire can cause excess spatter, poor fusion, or inconsistent beads, even when machine settings are correct. Base metal, joint position, and working environment all play a role.

These guides explain which wires and rods work reliably and how to keep them in good condition:

- Best MIG Welding Wire for Mild Steel

- Best Flux Core Wire for Outdoor Welding

- Best TIG Filler Rods for Steel and Stainless

- Best Welding Rod Storage Solutions

- How to Store Welding Rods Properly

🔍 Shielding Gas, Regulators & Flow Control

Gas-related problems are one of the most common causes of weld defects. Incorrect gas selection, unstable regulators, or inconsistent flow often lead to porosity and weak welds that look like machine issues.

These articles help you set up gas systems that stay steady and predictable while welding:

- Best Gas for MIG Welding

- Best Gas Regulators for Welding

- Best Flowmeter for MIG and TIG Welding

- What Size Welding Gas Tank Should You Buy?

🔍 Spatter Control, Table Protection & Shop Maintenance

Consumables go beyond wire and gas. Spatter buildup, table damage, and dirty wire all slow down work and wear out equipment faster than necessary. Small maintenance choices make a noticeable difference over time.

These guides focus on protecting your workspace and extending the life of everyday consumables:

- Best Anti-Spatter Spray for Welding

- Best Welding Table Cover Mats

- Best Welding Wire Cleaners

- How to Keep Welding Wire From Rusting

🔍 Abrasives, Clamps & Fabrication Accessories

A large part of welding time is spent grinding, fitting, and holding parts in position. Low-quality abrasives wear out quickly, while weak clamps and magnets make accurate fit-up harder than it should be.

These articles cover shop accessories welders rely on daily to keep fabrication moving efficiently:

- Best Angle Grinder Discs for Welding

- Best Welding Clamps for Fabrication

- Best Chipping Hammer for Stick Welding

- Best Welding Magnets for Layout Work

📌 Key Takeaways

- Welding consumables directly affect weld quality, consistency, and safety

- Correct wire, rod, and gas selection prevents many common welding problems

- Proper storage keeps filler materials usable and reliable

- Abrasives and holding tools are critical for accurate fabrication

- Quality consumables reduce rework and save time over the long term

🟢 FAQs About Welding Consumables

Q: Are welding consumables really as important as the welding machine?

Yes. Consumables influence arc stability, penetration, and bead appearance. Poor consumables can cause issues that are often mistaken for machine problems.

Q: How often should welding consumables be replaced?

Replacement depends on usage and storage conditions. Wire, rods, and abrasives should be replaced once performance drops or contamination becomes visible.

Q: Does storage actually matter for welding wire and rods?

Absolutely. Moisture and dirt exposure can lead to porosity, unstable arcs, and weak welds.

Q: Can cheap consumables affect weld strength?

They can. Inconsistent coatings, low-quality wire, or contamination often result in unreliable welds.

✅ Conclusion

Welding consumables are the foundation of consistent, reliable work. From filler materials and gas control to abrasives and shop accessories, the right supplies make welding safer, cleaner, and more predictable. This hub ties all of those resources together so you can choose, store, and use consumables that support solid results—whether you’re working in a controlled shop or out in the field.