What Is MIG Welding? – How It Works and Why It’s So Beginner-Friendly

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Last Updated: November 2025

MIG welding is one of the easiest ways to start welding because the arc stays steady, the wire feeds automatically, and you can focus on moving the torch instead of juggling filler metal. It’s a dependable choice for home garages, auto projects, and light fabrication. If you want a welding process that builds confidence fast, MIG is a solid place to begin.

👉 For a clearer picture of how MIG compares with other processes, check our guide on welding machines for different skill levels.

🔍 MIG Welding Basics

MIG stands for Metal Inert Gas welding, or GMAW. The welder feeds a thin wire through the gun while shielding gas protects the molten puddle. This setup creates a smooth, predictable arc that helps beginners pick up the basics quicker than they would with Stick or TIG.

🔍 How MIG Welding Works

When you pull the trigger, the wire advances and becomes both the electrode and the filler metal. The arc melts the wire and the base metal, while shielding gas prevents contamination. Adjusting voltage, wire speed, and gas flow lets you fine-tune penetration, bead shape, and arc feel.

👉 Before comparing MIG techniques, take a quick look at our guide on how mig welders behave to get a clearer feel for arc control and penetration.

🔍 Why MIG Welding Is Great for Beginners

MIG takes away the toughest coordination steps and lets you focus on controlling your puddle and travel speed. Since the filler wire feeds automatically, most beginners can start making decent beads after a short practice session. It’s especially helpful on thin steel, where Stick can easily burn through.

🔍 What MIG Welding Is Used For

MIG fits almost any small-shop job: auto body repairs, brackets, yard equipment, frames, and general fabrication. With a higher-amp machine, you can also weld thicker steel for tables, carts, and small trailer projects. It’s one of the most flexible processes to keep in a home garage.

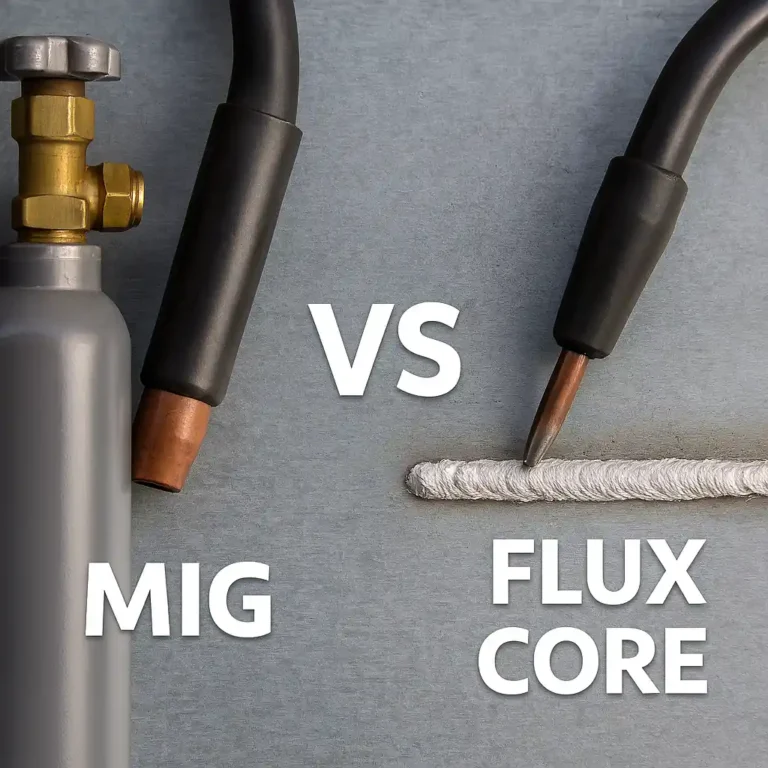

🔍 MIG vs Flux-Core

Gas-shielded MIG gives the cleanest, smoothest results indoors. Flux-core wire steps in when you’re working outside or dealing with rusty or dirty steel. Since both run on the same machine, switching between them is as easy as swapping the wire and adjusting your settings.

📌 Key Takeaways

- MIG uses a continuous wire feed and shielding gas for a stable, easy-to-control arc

- Great for beginners learning bead control and heat management

- Handles thin steel well and can weld thicker material with enough amperage

- Flux-core lets you weld outdoors without gas

- Perfect for auto work, repairs, and general home fabrication

🟢 FAQs

Q: What does MIG stand for?

Metal Inert Gas, also called Gas Metal Arc Welding (GMAW).

Q: Is MIG stronger than flux-core?

Flux-core often penetrates deeper on thick or dirty metal, but both can produce strong welds when set correctly.

Q: Can MIG weld aluminum?

Yes—especially with a spool gun or proper liner and wire.

Q: Do I need gas for MIG welding?

Only for gas-shielded MIG. Flux-core wire runs without gas and works better outdoors.

✅ Conclusion

MIG welding gives beginners a simple, forgiving way to start welding while still offering enough power and range for meaningful projects. Whether you’re patching metal, repairing equipment, or building something in your garage, MIG is one of the most reliable and user-friendly welding processes you can choose.