Welding Rod Number Meaning: Strength, Position, and Coating Explained

Disclosure: This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases—at no extra cost to you.

Last Updated: February 2026

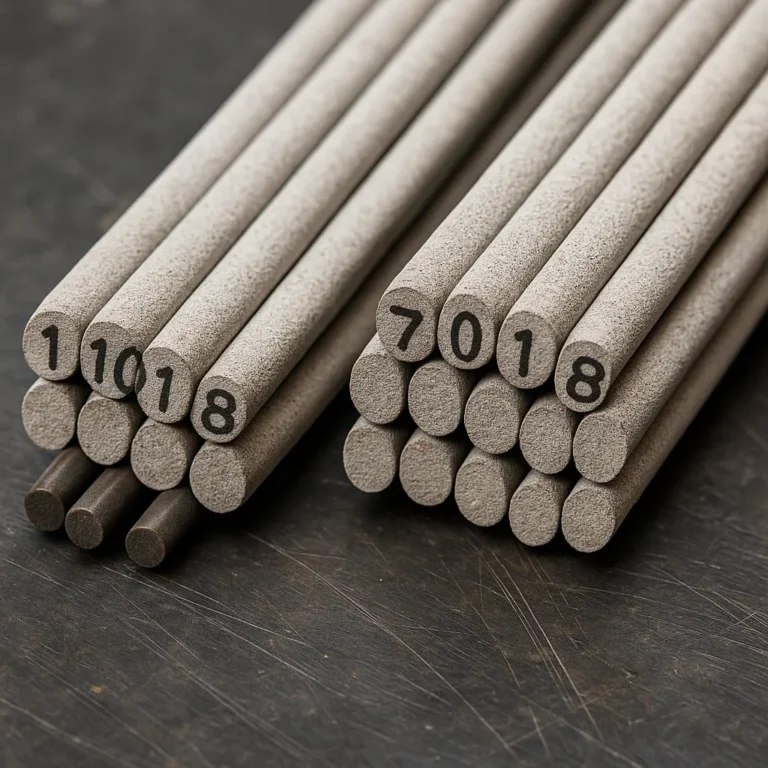

Understanding welding rod number meaning helps clarify why certain electrodes are recommended for specific materials, positions, and applications. Based on manufacturer specifications and AWS classifications, welding rod numbers are not random. Each digit conveys defined information about tensile strength, welding position, and flux coating characteristics. Misinterpreting these numbers can lead to poor penetration, cracking, or unsuitable weld performance.

This guide explains how welding rod numbers work, what each part of the classification means, and how to use that information to select the right electrode for the job.

👉 For broader context on selecting electrodes by application, see our guide on best welding rods and how different rod types are matched to real-world use cases.

📋 How We Evaluate Welding Rod Classifications

This research-based guide evaluates welding rod classifications using manufacturer datasheets, AWS electrode classification standards, aggregated user feedback from verified purchasers, and application-specific welding requirements.

We do not personally test consumables. All explanations are derived from published standards and manufacturer documentation. Always verify electrode selection against project requirements and applicable codes.

🔍 What Welding Rod Numbers Represent

According to AWS electrode classification standards, welding rod numbers describe three primary characteristics:

- Minimum tensile strength of the weld metal

- Approved welding positions

- Flux coating type and current compatibility

Each part of the number provides specific, standardized information that allows electrodes to be compared consistently across manufacturers.

🔍 Tensile Strength: The First Two Digits

The first two digits of a welding rod number indicate the minimum tensile strength of the deposited weld metal, measured in thousands of pounds per square inch (PSI).

For example:

- 60xx electrodes are rated at 60,000 PSI

- 70xx electrodes are rated at 70,000 PSI

AWS guidance indicates that tensile strength selection should match or slightly exceed the base metal strength to avoid creating a weak joint.

🔍 Welding Position: The Third Digit

The third digit identifies the welding positions for which the electrode is approved.

- 1 indicates all positions (flat, horizontal, vertical, overhead)

- 2 indicates flat and horizontal positions only

For example, rods ending in “1” are commonly selected for field and structural work due to their positional flexibility.

🔍 Flux Coating and Current Type: The Last Digit(s)

The final digit or digits describe the flux coating type and current compatibility. This portion of the classification has the greatest impact on arc behavior, penetration, slag characteristics, and hydrogen control.

For instance:

- 6010 electrodes are cellulose-coated and designed for deep penetration using DC+

- 6013 electrodes are rutile-coated and compatible with AC or DC

- 7018 electrodes are low-hydrogen rods designed for structural applications

AWS documentation notes that flux type directly influences weld appearance, penetration depth, and crack resistance.

🔍 Common Welding Rod Numbers and What They Mean

Some welding rod classifications appear frequently due to their versatility and reliability.

6010 welding rods are used for open-root welds and dirty steel, offering deep penetration and fast-freezing puddles.

6011 welding rods provide similar penetration to 6010 but allow AC operation.

6013 welding rods are designed for smooth arc performance and light fabrication work.

7014 welding rods contain iron powder to increase deposition rate and productivity.

7018 welding rods are low-hydrogen electrodes used for structural and code-regulated applications.

Each classification reflects specific design priorities rather than overall quality.

🔍 Why Welding Rod Numbers Matter in Practice

Selecting a welding rod based solely on availability can lead to poor results. AWS standards emphasize matching electrode characteristics to joint design, base metal condition, welding position, and service environment.

For example, selecting a high-strength rod does not compensate for poor penetration characteristics, and choosing the wrong flux type can increase crack risk even when tensile strength ratings appear sufficient.

Understanding welding rod numbers allows for informed selection rather than trial-and-error.

📌 Key Takeaways

- Welding rod numbers follow AWS classification standards.

- The first digits indicate tensile strength in PSI.

- The third digit shows approved welding positions.

- The final digit describes flux type and current compatibility.

- Correct interpretation improves weld quality and reliability.

⚠️ Safety & Training Requirements

Welding involves significant electrical, fire, burn, and eye injury hazards. This guide provides general information only and does not substitute for proper welding training and certification, manufacturer safety instructions, electrical work performed by qualified electricians, or appropriate personal protective equipment (PPE).

Consult certified welding instructors and follow all OSHA and AWS safety standards.

🟢 FAQs

Q: Do higher welding rod numbers always mean stronger welds?

According to AWS standards, higher tensile ratings indicate stronger weld metal, but joint design and penetration are equally important. Consult qualified professionals for personalized advice.

Q: Can rods with the same strength rating be used interchangeably?

Manufacturer guidance indicates that flux type and position rating must also be considered, not just tensile strength. Consult qualified professionals for personalized advice.

Q: Are welding rod numbers the same across brands?

AWS classification standards ensure consistency across manufacturers, though performance may vary slightly by brand. Consult qualified professionals for personalized advice.

✅ Conclusion

Based on manufacturer specifications, user feedback, and AWS standards, understanding welding rod number meaning allows for more accurate electrode selection and better weld outcomes. Welding rod numbers communicate tensile strength, positional capability, and flux characteristics, making them essential for matching the right electrode to the right application.